I worked out a usable seating depth with my 125 (dropping 130) GR .356 cast bullets.

I can coat and load as cast with OAL 1.050 and get reliable feeding. Over 1.105 I run the risk of failure to go into battery.

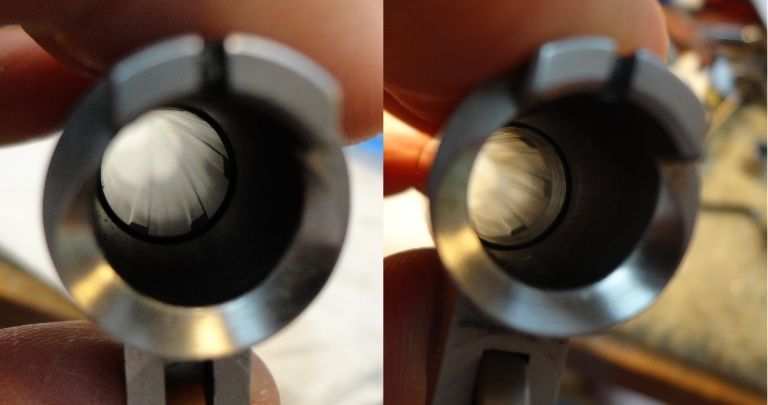

I cast a soft lead bullet and plunked. I did force into place lightly and scored the bullet. It is hitting on the shoulder that the case should be headspacing on. I did a few times to wear in a groove so to speak. Measures 0.3565 at the score marks. Is this the diameter of my throat then?

I had a difficult time slugging my barrel as it is S&W with 5 grooves. Can I leverage this measurement as a slug of sorts?

I loaded and shot 10 rounds today at the 1.050 length with 3.7gr HP38. Accuracy was acceptable. I am most concerned with a functional load at this point and trying to determine what sizer if any I should get. I am not at a compressed load. I have to give there

Sent from my iPhone using Tapatalk

|

|

|

Reply With Quote

Reply With Quote

DougGuy

DougGuy