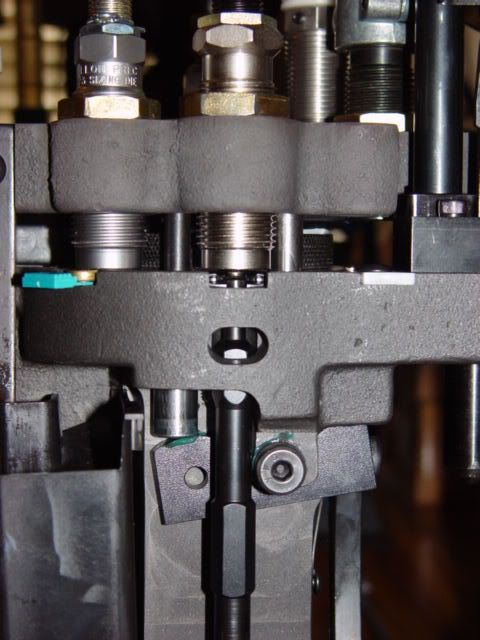

May be a dumb question but I have a bucket full of military brass that I can't prime. I have tried several ways to remove the crimp with no luck. Any suggestions on a primer pocket swagger for a Lee single stage press to make this brass work? Any advice would be helpful.

|

|

|

Reply With Quote

Reply With Quote

W.R.Buchanan

W.R.Buchanan

The fastest manual method is the 1050 it will also load your ammunition while it swages. It's only draw back is price.

The fastest manual method is the 1050 it will also load your ammunition while it swages. It's only draw back is price.