|

|

|

Rick,

Thoughs pictures make a good point. They all have scrapers. I own and have shot the NOE 340365 and I also (mainly) shoot tapered match bullet that are very much like scraper groove bullets, in that the first groove is supported by less than half the diameter of the groove diameter of the barrel. The picture is a 200 yard group that I shot with the the NOE bullet that measures 1.990". There is only 3/4" verticle in this group.

Frank

I wonder why? Could it be that long unsupported nose with the scraper groove under it? The OP "like's speed" and mentions 2250 fps with it wanting moa or less accuracy out of his FN rifle "knocking them out" on an automated casting machine and automated sizing & lubing. Anyone want to bet he'll succeed......perhaps frank........?

Larry Gibson

What you want to do is entirely possible, just not the way you're going at it. An AR-10 will shoot cast MOA and under at 2,400 fps IF you load it correctly with the right boolit. That boolit is the MiHec 30 Silhouette. Unfortunately for you it doesn't come in a steel mold, just brass.

More like it doesn't fit from being undersize on the nose and it tips out of line when it gets booted in the behind from a load with a little too much pressure. That, BTW, is the cause of some of your testing failures. Get the boolit started straight, concentric with the bore, and good things happen. As far as automated equipment, IF it is set up properly (an automated sizing and lubing with a GC boolit is something I have to see though) and the test platform is suitable and the boolit fits.... then it can work. Just like any other rifle provided the operator makes wise decisions and doesn't blame something else for their lack of attention to detail.

OP, have you considered powder coating your cast bullets? That will eliminate the velocity restrictions of cast bullets, to some extent. I think what you're looking for is possible with a powder coated boolit.

I'm running an old H&G #20 (which I've read is similar to Lyman's #311413), which casts 170gr from coww. I'm powder coating it, then applying the gas check and sizing. I'm pushing this one with full power loads of IMR 4895 (42.5gr iirc) in my 308 PTR91, and getting about 2" @ 100 yards. That's about the best this rifle shoots with jacketed bullets too, so I think better accuracy is possible from a better rifle.

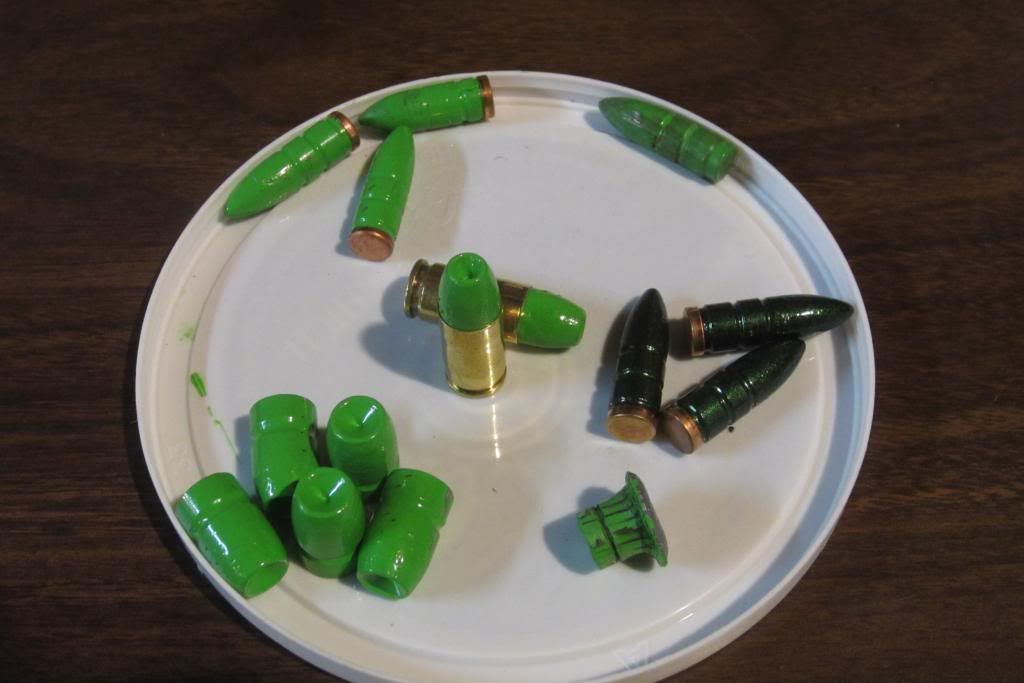

Sorry I don't have a better picture, it's the dark green bullets on the lower right, and one of the light green bullets on the upper left. At the upper right is a recovered bullet that was fired subsonic through some wood.

Amazing how one knows of my "testing failures" considering you refuse to shoot with me to see. You probably would like to bring up the 311291 again but considering what bass and I both did with it you've already lost on that one. Also I see no members substantiating your 2400+ fps accuracy claims with an AR10. Perhaps they or you would post some pictures of 10 shot 100 yard groups? I also noticed no comments from you on my posted 100, 200 & 300 yard 10 shot groups I posted at 2600 fps.......Perhaps the "failure" you refer to?

Oh, or perhaps the "failure" you refer to is indeed caused by the weak point in many older designs. ...the scraper groove. ....

Larry Gibson

One cartridge, one rifle, one boolit wonder theories don't make reality or prove much, just what that combination did, with all the tolerance stack involved. Did you have witnesses for what all you posted since you asked, we've never heard from them either..... I did, and shot from semi-auto's no less...... As far as boolit faults are concerned, talking to an engineer doesn't mean much as they gave you the answer you could understand.... a couple of years in TAM classes and you'll understand what you don't now.

Yes I have witnesses and have offered numerous times to you and several other nay sayers here to shoot with you anytime. Any members around Lake Havasu City AZ just give me a PM and we'll go shooting; out in the desert or on the 100 - 300 yard range at Sara park. Conversely though I have to ask why it is that you, 45 2.1 and the other nay sayers, adamantly refuse to shoot with not only me but numerous other members of this forum?

Why talk with an engineer? Because frank didn't understand how the scraper groove was a weak point of the bullet; a smaller diameter rod does not have the strength of a larger diameter rod of the same material and will bend or collapse under less pressure. The engineer could tell you scientifically how the smaller column at the center of the scraper groove can not withstand the stress (created by the acceleration G force) that it could if of equal diameter to the nose and tapering to the diameter of the front drive band. He could also explain to frank how the lube grooves are supported by the lube during acceleration if frank didn't understand that fluids compress very little which is the basics of hydraulics. It would take about 5 - 15 minutes to explain in layman terms. frank ask the question and I suppose I could have suggested 2 years of TAMS study like you did but that's a little bit of a ridiculous way to give a simple straight forward answer isn't it?

So, 45 2.1, if you know anyone on the forum out this way that would like to see the verification and even shoot a few groups themselves they are more than welcome to contact me so we can go shooting. I will also show them the structural faults of scraper grooves with numerous bullets in numerous rifles of various twists.

One last question; you know *** (unmentionable former member) sold me his MP 311-180 that I believe you designed(?). Why no scraper groove on that bullet if you designed it for the .308W for use in ARs? BTW; if you did design that bullet it is an excellent design. The design follows the guide lines I have mentioned in numerous threads & post for a HV cast bullet. Note the commercial moulds of similar design from .224 upwards of 8mm or .35 caliber do very well pushing the RPM threshold to higher levels. One reason being the elimination of the scraper groove adds to the strength of the bullet lessoning imbalances from occurring during acceleration.

Larry Gibson

lary,

You can say anything you want about scraper grooves but, until you can show that they actually fail, you have no credibility. All that you talk about is assumption. As the Lil ol' lady say's....... "Show me the beef"

I've posted a picture of a 200 yard group that I shot with a full spitzer, scraper groove bullet that did well w/o deformation. I also have asked for the name and number of the "engineer" that suppositely told you that land supported bullets will bend or distort.

Where is your "Beef" ?

Frank

I've been a member here for a few years and lurked quite a bit for a few before joining. What I love about this group was the vastness of the knowledge here and how freely it was given. I can honestly say that I've learned as much in the last two years here as I did in the 40 casting years before.

There are a LOT of folks here with a LOT of knowledge and experience. As is usually the case with those folks they don't always agree. That's OK as the discussions between them are always interesting and sometimes educational.

It does get distressing when people we have followed and have regard for start going at it on points they can't agree on. If you don't mind me saying so I reckon Ya'll be a darn site happier if you'd read what ya wrote before ya send it and ask yourself how you'd feel if someone spoke to you that way. All of you are deserving of the respect of those that learn from you............and each other.

Lets all help each other. Were all friends right? Some here spend more time than with there wifey so lets all be buds.

Duke

No, you are not "nuts". You are correct, especially if the OP wants to use a design such as the 311332. Some here have missed the point of the OP's question. You have summerized it nicely.

And as mentioned there is no need for anyone to get raspy about it. I have mentioned numerous times I would be glad to shoot with any of them and demonstrate the problems associated with shooting cast bullets at HV in faster twist rifles. I also would be glad to discuss the design charactoristics of the bullets that perform well at HV/high acceleration. I would also denonstrate the success at shooting cast bullets at HV in such rifles. The offer is always open.

On page 78 of Lyman's CBH #4 we see a listing of selected loads for the 30 BR from CBA benchrest matches. The bullet moulds are listed. A couple observations are noteworthy to this discussion; none of the bullets used have a scraper groove. The bullets used in the velocity range of 2400 - 2794 fps were light in weight, had short noses, long % of bullet length bearing surface and were shot in very slow twists (1:17 or 1:18"). Perhaps there is something to be learned there?

Larry Gibson

Sorry for the lack of response lately, I've been working in my yard and redoing it getting ready for summer... then we deicded on Saturday morning to get a 8 week old puppy. Needless to say I've been busy.

basically you are all on the right path here, I am looking for what appears to be unicorn tears. My rifle is cold bore accurate and with SMK's or Nosler 175's shoots sub moa all day long at any range.

I love the design of the NOE 311365, it's ideal for what I am looking to do to be honest. that having been said I guess I'm changing my mind over the concept and now looking towards a truly custom gas check maker from Freechex if he can make one for me and a cherry mold where I will buy the cherry as well. I think I am going to duplicate every detail of a Nosler 175 Custom Competition with gas check and have the custom gas check maker make them to wrap over the boatail.

Possible, yes, but will I be able to get the mold cutter and Freechex to make the gas check is still being debated? I'm sure i'd have to have the bullet itself cast and send it out to him to duplicate the dimensions on. Of course the bullet will have no lube grooves as I will use J&M lube.

Copying it bit by bit should yield very similar results to the actual bullet but for a fraction of the cost. The bullet itself will have to be dimensionally changed slightly as the density of the lead alloy will be slightly different weight than the pure lead they run in FMJ's.

SO tell me I'm nuts here folks, or am i possibly onto something here???

Yes I will automate every aspect of production except for the freaking gas check / sizing aspect. I'm not sure how / if at all possible that automating that process is, so it's manual for me just for that.

------------------------------------

------------------------------------------

Every cloud has a silver lining (except for the mushroom shaped ones, which have a lining of Iridium & Strontium 90).

NRA Life Member

Magma Master Caster

Dillon 550, 650 (automated) reloader.

So much other **** related to reloading I can't even recall all of it.

Well Sir, I wouldn't say you're nuts but I do figure you've got quite a hill to climb. I'll dime myself out here and say I have NEVER shot a cast sub MOA group with ANY cast Boolit. I figure there's those that have cause I've read about them and I sure keep trying. My improvements are incremental as I test different lubes/alloys/powders/primer/filler /seating depth/sizing diameters etc. etc. etc. and all the combinations therein. Right now I'm testing with an older mold I have, the 311413, in both solid and HP configuration. I am getting 1.5 MOA from a 1-10 308 at 2100 FPS (with the solid) which is very exciting to me. It too is a sub-MOA rifle with 168gr SMKs (.358" @ 100yds for 5 rounds). The 311413 looks like the lime green Boolits in post #46 but with a longer GS shank and a bit shorter lower drive band.

You may want to do a search for boat tail gas checks here as I recall somebody developing them a bit over a year ago. Haven't heard much lately but there may be a thread for you to review.

I wish you the best of luck in your endeavors Sir. a LOT of good info here and a LOT of experience. You sure came to the right place to get started!!!

Yes i have come to the right place, I've been on the board for years more or less as a lurker and never really adding much or responding to many posts. As you can tell from my join date in 2008, i've been on here for 6 years but never posted much.

I will have to look for that post, I know the info is out here ya just gotta find it!

------------------------------------

------------------------------------------

Every cloud has a silver lining (except for the mushroom shaped ones, which have a lining of Iridium & Strontium 90).

NRA Life Member

Magma Master Caster

Dillon 550, 650 (automated) reloader.

So much other **** related to reloading I can't even recall all of it.

I don't know if you have found it already, but this is about the most comprehensive boat tail gas check test I have seen: http://castboolits.gunloads.com/show...light=boattail

AWESOME that's a great thread, I'm subscribed to it... hope to gain some awesome info there.

------------------------------------

------------------------------------------

Every cloud has a silver lining (except for the mushroom shaped ones, which have a lining of Iridium & Strontium 90).

NRA Life Member

Magma Master Caster

Dillon 550, 650 (automated) reloader.

So much other **** related to reloading I can't even recall all of it.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |