I have been eagerly awaiting the arrival of my first range day with my new 300BLK build, finally today was my day, albeit the weather was not in my favor

...This is just the beginning of much more testing, so stay tuned...

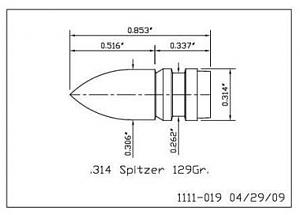

The boolit in question here is the NOE 314-129. When lubed and GC'ed it comes out to ~139grs and as far as I know, it has never been tested in the 300blk (at least no info exists for it on the internet, believe me I've searched far and wide)

Rifle:

MAS Defense upper 16" bbl carbine length gas port (opened to .111") 1:8 twist

PSA Lower

AIM Surplus standard m16 BCG

Load recipe:

Brass: LC converted 556 from Grumpa

Boolit: NOE 314-129 @.311" copper gas check and Xloxed

Primer: CCI 400

Powder: Alliant 300MP 18.0grs (charges were thrown from lee perfect powder measure, they varied 17.9 - 18.1grs consistently, no problem)

COL: 1.900"

This morning I woke up and it was pouring rain outside. I've been waiting for my day off all week, and wasn't about to let that stop me, so I loaded up 70 rounds and headed to the range.

First five shots were a complete failure, bolt didn't cycle hardly at all, rounds jammed (if it even picked up the new round) and the bolt most certainly didn't hold open. "Great, I've got a bolt action AR" I thought to myself...

By the sixth or so round, all of the sudden the rifle began performing perfectly. This noob was being too impatient and expecting too much right off the bat, it seems the grease needed to get worked into the bcg and such, and I was sure to run it wet first time out. Function was then flawless for the rest of the range trip.

No chrono, not that it would have liked the pouring rain and zero sunlight very much anyway, soon I will have one, but this was a function/accuracy test to start.

With function down it was time to move on to accuracy. Sitting outside on a soaking wet (and very un-leveled) bench, I put rounds on paper at 50yrds while my rifle slipped around on the uneven wet wood. After a few sighters I got the red dot squared up, and then proceeded to make one ragged hole at 50yrds with shots that I would have described as being executed poorly as well as rushed. It consistently held 1" at 50yrds under very subopitmal conditions.

So to wrap up the first outing: my rifle, which was brand new and unfired, held 1" at 50yrds with lazily made shots and lazily made ammo (powder ~.2grs variance and boolits +/-2grs variance) off a slippery bench and in the pouring rain. Not only that, but it was my first load recipe concoction using a boolit with no references to draw from, and it hit right on the money! Gotta love that, 300blk beginner's luck perhaps?

2moa accuracy for 10 shots can certainly be tweaked and under the right circumstances I am sure I can get that down to closer to a half inch. But even still, I am not complaining, that is good enough for <100yrd steel plate work.

No chrono yet, but given load data for similar bullet weights, it should be right around 1900-2,000fps

No leading whatsoever, barrel is clean as a whistle as is the rest of the rifle, this 300MP powder is the true ticket for the 300BLK I daresay.

Future tests to include 100yrd accuracy confirmation, upping the charge, lowering the charge, etc. This boolit has me very much impressed!

|

|

|

Reply With Quote

Reply With Quote