I came accross a record in which I wrote .69 MOA at 200 metres. I don't remember that but I do know the rifle was scary accurate and flat shooting out to 160m. By flat shooting I mean the bullet did not rise or fall more than 40mm from the line of sight out to that range. This rifle had a rust damaged bore and an oversized chamber, possibly reamed to remove rust pits.

I do think Lil'Gun will perform well in other cartridges with the same scaled up geometry but I'm not sure how to do the scaling up.

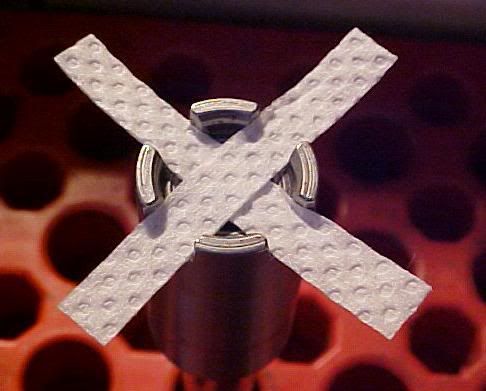

There is another way to seat a boolit in an unsized neck when the fit is quite close but not close enough to hold the boolit in place.

This requires a powder charge that fills the case right up to or into the neck and a cardboard wad that actually seals the neck. Then a little blob of a stiff lube like my 'waxy-lube'. The trick is to warm the boolit then set it on the blob of lube and it melts itself into place. That trick did work but the clearance was too large to give a firm enough grip.

|

|

|

Reply With Quote

Reply With Quote