|

|

|

History will record, with the greatest astonishment, that those who had the most to lose, did the least to prevent its happening.

The problem with Liberals is not that they're ignorant, it's just that they know so much that isn't so.

- Ronald Reagan

that is great I see or read something new here all the time tanks.

You would have a machine full of melted lead!

Shooter of the "HOLY BLACK" SASS 81802 AKA FAIRSHAKE; NRA ; BOLD; WARTHOG;Deadwood Marshal;Bayou Bounty Hunter; So That his place shall never be with those cold and timid souls who neither know victory nor defeat; 44 WCF filled to the top, 210 gr. bullet

Definitely a pretty piece of work!

Thanks for sharing with us.

Dale53

I have a fresh batch of "blades" if anyone is interested in putting one together shoot me a pm.

Have you considered a 4 second cycle instead of 8 seconds? Or did you use templaq ((700 deg or 750 deg) to decide on the cycle time?

cheers,

chuck...

The cycle time depends on how the torches are adjusted and what brass is being annealed. It's always a little different.

Boy, the ingenuity you see always amazes me. Great work! I may have to put one of these together "just cuz."

A router speed control from Harbor Freight would allow easy adjustment of the dwell time. Of course you would have to shorten the dwell time to begin with, then you could lengthen it by slowing down the motor.

I just so happen to have an extra mounting arm for my 650 case feeder. Hmm...thinking about doing this project just for fun...

jonblack

I used a DC motor and a dimmer swtich for the dash lights on an old RX-7 for the speed control. If you are wanting to put one together I have about 10 of the blades left.

Awesome job, Mr. Morris!

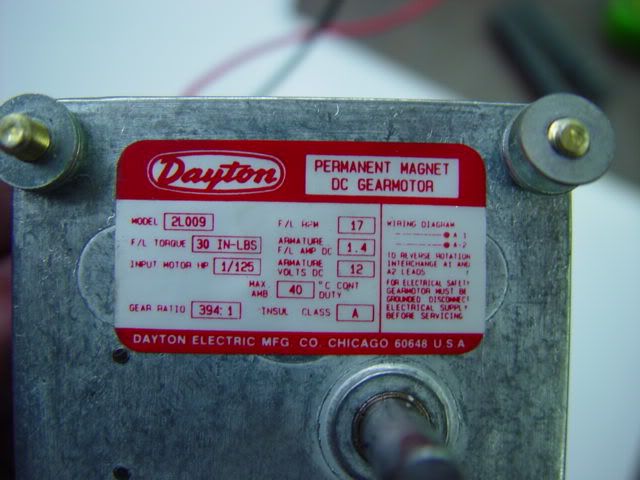

May I ask where you bought the motor?

Thanks,

Carl

"The democracy will cease to exist when you take away from those who are willing to work and give to those who would not" - Thomas Jefferson

From Granger. The link to all of the step by step photos is in the first post.

Jmorris,

AWESOME!!!!! I have a couple of questions, how did you find out how long the brass needs to have heat???

Also, I don't kmow anything about the properties of Brass, but if those were made out of steel they would harden when dropped in water. So brass doesn't get harded with fast cooling??

Your machine is as I stated AWESOME design, and thanks for sharing.

Later

G

Templaq, is the best method for knowing what temperature you are reaching.

http://www.markingpendepot.com/tempi...o1600degf.aspx

The only thing that hardens brass is working it. The dunking in water you often read about is to make sure the base doesn’t get annealed. I don’t use water in my process as it is not necessary and would just add another step in the process to dry them off.

Thanks J,

Like I said I didn't know anything about brass. Thanks for the link, I am trying learn what I need to know, I have just put toghter a AR in 243WSSM and i am told the WSSM brass doesn't do well if you don't anneal it before resizing.

Thanks

G

I really need to make me one of these.

Robert

"The only way to deal with an unfree world is to become so absolutely free that your very existence is an act of rebellion."

- Albert Camus -

Very nicely done and "full auto" once adjusted!

I just ordered a blade. There are still some available.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |