RFD,

I believe you have inverted the two drawings in that the one on the right is the Nock's patent

breech. The one on the left is the breeching method of Many other flint lock manufacturers including Manton, Mortimer, et al.

|

|

|

RFD,

I believe you have inverted the two drawings in that the one on the right is the Nock's patent

breech. The one on the left is the breeching method of Many other flint lock manufacturers including Manton, Mortimer, et al.

curator - yes, you are spot on, but for illustration purposes the breech on the right gives one the concept of a cap lock patent breech, with clean out screw (actually, pressure relief port) only the flue and antechamber would be as one, as shown in the touch hole patent breech on the left. just showing how constricted the ante-chamber/flue is and why a small patched brush is needed to clean it all out because a patched bore jag will never get in there, and will only force the crud into that flue, which will not make for good ignition.

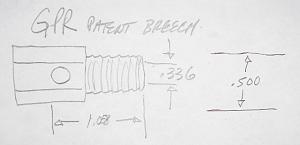

here are measurements i took off a GPR .50, to show the ante-chamber and bore sizes ...

Ahhh, interesting. When I had the barrel off, I wonder about that last inch. That obvious seam there, and what was inside. Now I get it, thanks Gentlemen.

Greywuuf. That makes sense. I wondered what kind of "metallurgy" was going on to create that much green. Now I get it, thank you.

I wish I could show the videos of before/after from the borescope, but the software is proprietary enough that the videos don't show in the iPhone library as even existing.

Thanks again fellas!

Last edited by Bob in St. Louis; 05-03-2018 at 07:58 PM. Reason: Not a good speller

You've got plenty of people giving you loads of solid advice in this thread. So I don't really have anything to add other than welcome to the crazy world of muzzleloading! And sweet deal on that rifle. $150 is a steal!!

Thank you!

Yes indeed, lots of quality information here. I'm going to make myself a cheat-sheet to keep it all straight and organized.

Hey fellas, I'm a bit embarrassed to ask this question, but... here I go.

I bought myself a nipple wrench, but the hole in it is too small. In my searches, I've found the difference between a "side-lock", and which wrench will work for my gun, but no where (and I mean NO WHERE) did it mention the size of the nipple. I did not know that was "a thing".

I've check the users manual and it does not mention what size nipple the rifle has.

So.. the wrench I bought says it's for #11, but its hole is too small.

Unfortunately, when I search the internet for "sizes of nipples"..... well... never mind.

Any assistance would be much appreciated.

.

What you might look for is a T/C combo tool. with a hammer & hook for pulling the barrel wedge for cleaning it out of the stock, with the proper nipple wrench:

This is a new one for sale: https://www.gunbroker.com/item/770847763

The T/C Hawken takes a nipple with a 1/4-28 thread.

Track Of The Wolf has the nipples: https://www.trackofthewolf.com/List/Item.aspx/807/1

.

Now I lay me down to sleep

A gun beside me is what I keep

If I awake, and you're inside

The coroner's van is your next ride

Bob in St loui, the wrench you have may be for a revolver.

If you have access to some basic machinery, making one is pretty simple. Drill a hole in a rod end, slice a section out of the middle so it fits over the nipple, & attach a handle. The handle can be as simple as a vise grip clamped on.

Thanks fellas!

I found the T/C combo tool on Amazon for $14 (free shipping since I'm Prime). So just a heads up, it's $11 less than Gunbroker.

Thanks for the heads up on that one!

So... Had my first "outing" today. I ran 50 grain, 100 grain and 120 grain with roundball.

Got about a half dozen shots off before I lost focus and had my first 'dryball'.

I thought I was too smart to do such a thing, but life reminded me I'm not as sharp as I'd like to think.

It was then I discovered the ball extraction tool I bought doesn't have the same threads as the cleaning rod.

Good thing, since I only had only started the ball, and it was flush with the end of the barrel.

Drilled a hole, ran a screw in it, and use channel locks, came right out.

In case you're curious to see, here's my .54 Hawken in action, my back yard, and my fat belly.

50 grain:

https://youtu.be/B0EvmKn8Flg

100 grain:

https://youtu.be/T6WbiWTelF0

120 grain:

https://youtu.be/lvaE2xzReeM

Thanks again for all the support guys!

Bob

be aware that if you're shooting fff instead of ff (like it says in the description below the videos), the finer fff will be a larger charge than the coarser ff if measured by vol.

120 grains of 3f in a t/c .54 is an over max load for sure ...

Ok, thank you. I was unaware of the difference in load with the two powders.

Great information guys, thank you VERY much!

As far as how much you had in there, I guess you could weigh in grains the 120 fff charge, then see what volume of ff it took to weigh that much. Historically, blk pwdr has always been measured by volume not wt tho.

That's an idea. If I can find a place near me to buy 3g, I'll compare the two. Just for giggles.

Now that you know what it feels like to shoot 120 grains, go to a range where you can bench rest that riflegun and work up an accuracy load starting back at 50 gr and increasing the powder charge in 5 grain increments. Minimum 5 shot groups with each change. Somewhere around 60 or 70 grains you are going to be smiling.

..

That sounds like a fantastic idea. What distance would you recommend?

fwiw, all my initial testing is always at 25yds.

Ok, good deal.

I've yet to measure out anything in my yard that far, but I should be able to get that distance without a problem.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |