First attempts are not bad. The ideal is sound, but my very cheap approach only works on short boolits (.800-.900 or so). When my .501 H&I die arrives I will slightly modify it to hold the neck bushing... Some ideals came to me.

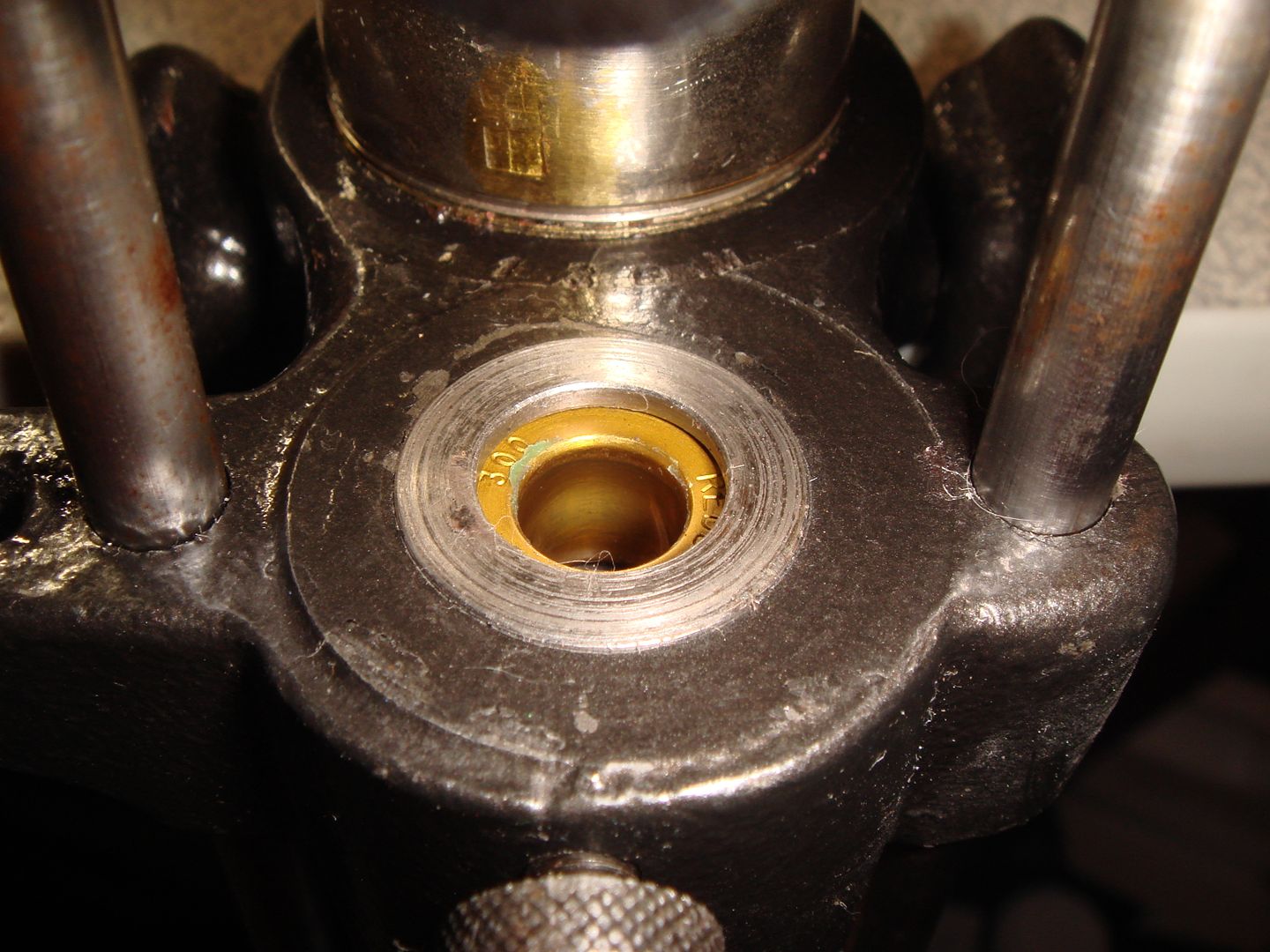

Attachment 113772

This shows a 280468S being set up to size the nose to the very first band. I used the Redding bushing with the letters UP. See the distance between the base of the boolit and the punch? Now you can turn out a much shorter Top Punch, but then you will be adding MORE parts.

One of the first things I found out was the TP that works with the normal H&I die may not work with the diameter of the neck bushing being used. Not wanting to swap TPs for every operation, I just rooted about for a TP with a punch end of a suitable diameter.

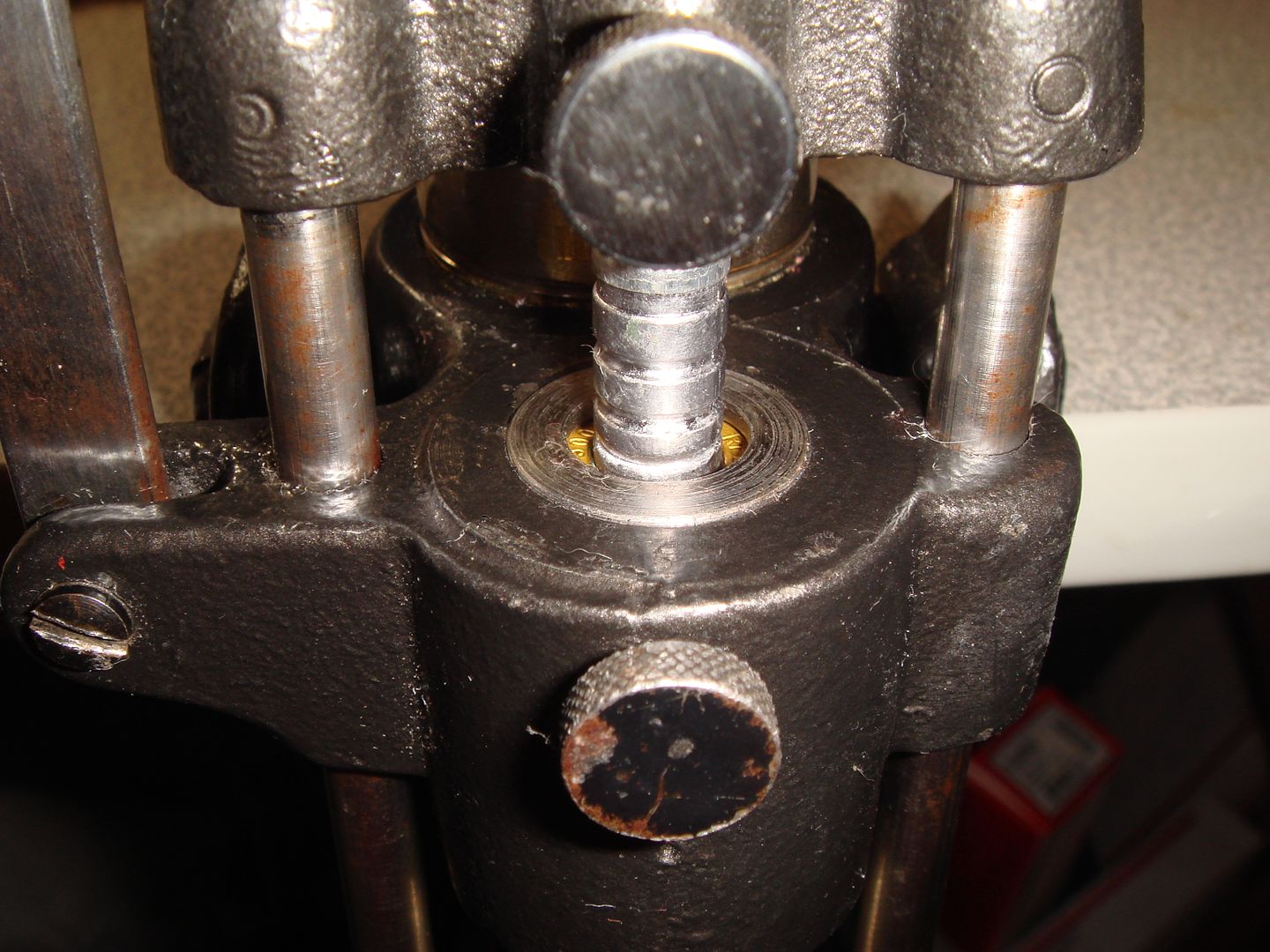

Attachment 113774

Here is a shot of the super complicated ejection system. Merely turn the bushing end for end and rest it on another bushing for the boolit to be pushed down into.

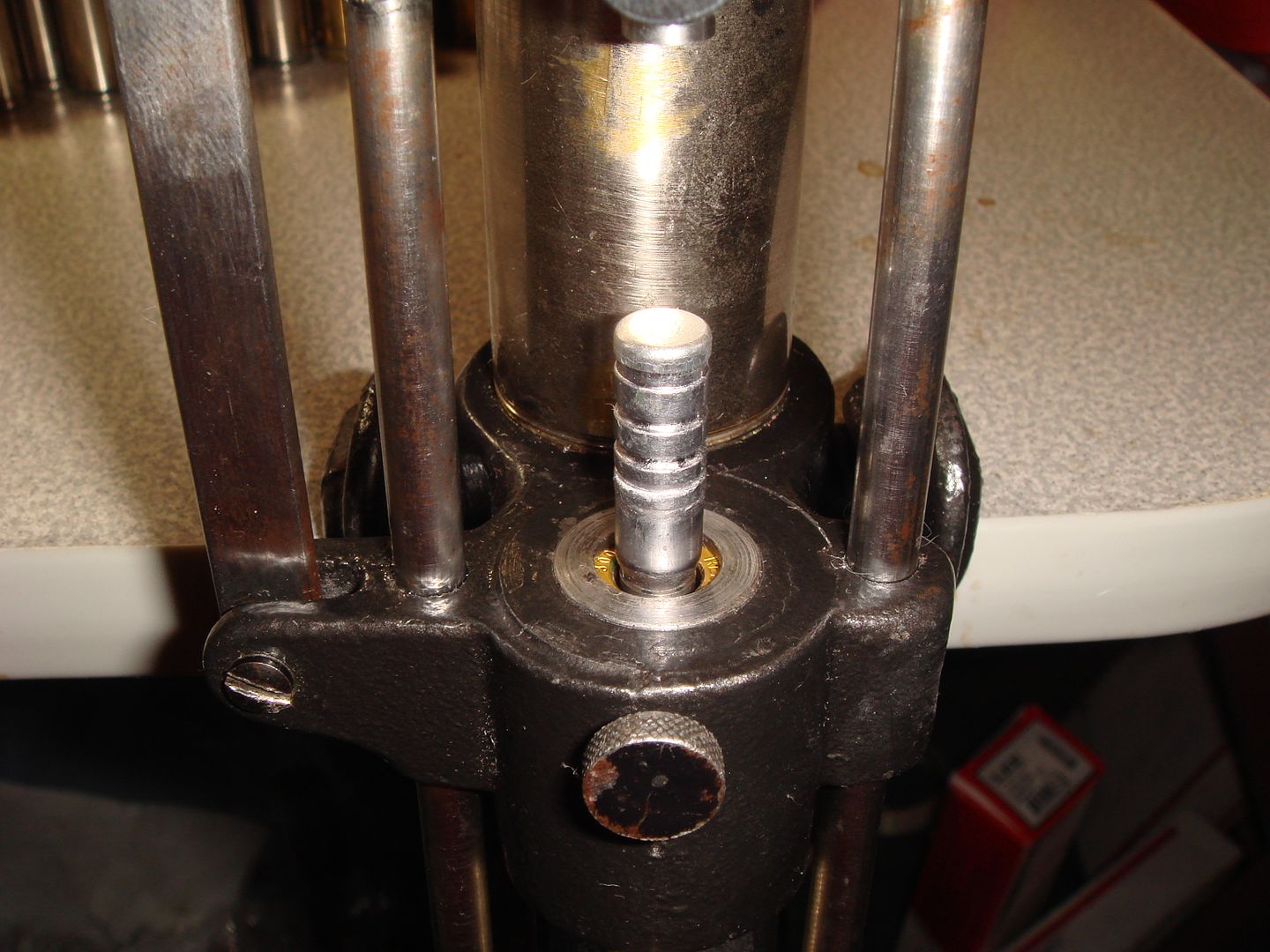

Attachment 113776

Here is a 280468S boolit with an unsized nose. The tilt was not intentional, darned Lūb Monkey wouldn't hold still... Note that the boolit stops entering the bore prior to the first band and that it is still on the ogive. The unsized nose is @.272, what a difference a few thousandths make...

Attachment 113777

This is a 280468S with a nose sized to .270 inserted into the muzzle of a TC 6.8mm Remington SPC barrel. Note that it is all the way up to the first band and no ogive is seen. Effort to size the nose is far less than full diameter sizing.

Things to do yet - it appears that the short nose on a NON bore rider allows TOO much angular play when starting the boolit. I am of the opinion that moving to the H&I with a neck bushing will pretty much eliminate the OAL boolit length problem. One finesse is to use a neck bushing slightly oversize for the as-cast boolit diameter to hold shorter boolits in alignment when starting.

When my 277 H&I arrives, I will size some RCBS 7mm-145s for use with my 7-30 Waters. The bore rider nose IMHO is long enough to self-center...

|

|

|

Reply With Quote

Reply With Quote