I have a 50 cal REAL mold (LEE of course) that almost drops down the barrel of my inline. I need to "open" the mold up a little bit so the bullets drop bigger.

is there anything I can do to make that happen?

|

|

|

I have a 50 cal REAL mold (LEE of course) that almost drops down the barrel of my inline. I need to "open" the mold up a little bit so the bullets drop bigger.

is there anything I can do to make that happen?

Search for techniques called "Beagling" and "Leementing". Beagling is just shimming the two mold halves apart to produce a slightly oval, but slightly larger boolit (they generally shoot just fine despite being a few thousandths bigger one way than the other); for Leementing, you convert a boolit cast in the mold into a lap and use it to lap the mold cavities until they cast the size you want. Both are very practical ways to add a few thousandths to the as-cast diameter, and Beagling can be undone if needed.

Beagling works and is easy.

I didn't have any of the adhesive backed tape so used regular aluminum foil and silicone blue gasket goop. Worked fine and as I'll Make Mine says, it is reversible.

You should be able to get up to about 0.003" Beagling then you may start to get some flash at the seams.

Lapping will give you a nice round boolit of done correctly but you risk ruining a mould if done incorrectly. Again, lapping can be successful to about 0.003"/0.004" but taking much more than that may be tricky. If you need more then lapping some and Beagling may just do it.

If you just need a couple thou then Beagling is your easiest answer.

Longbow

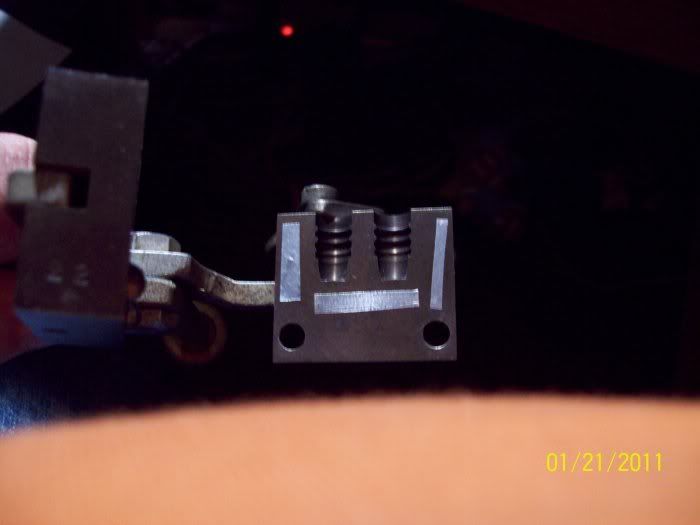

Here`s 1 I "beagled" for venting a couple of Ks over was just a good side affect.

GP100man

Funny. I've asked that 3 times on two forums in 3 different threads because I have no idea. "are these things supposed to go down so easy?" and the like. The answer I was always given was that they seem to go down the barrel the same as any other bullet. No additional detail. Thats exactly what's been leading me to believe these are too small (and accuracy issues). I could seat these with a drinking straw and leave no mark on the bullet nose. You are the first person to volunteer that they are supposed to almost drop down the barrel.

These are cast with stick on wheel weights.

It's my understanding too that the R.E.A.L. boolits are supposed to be slightly loose in a clean barrel. The idea of them is that when the barrel starts to get fouled, the ridges on the boolit act like scrapers, and scrape the fouling down the barrel as it seats so the level of fouling remains the same for each shot. I've never tested that theory as I just got a couple of R.E.A.L. boolit moulds, but have yet to shoot them.

If you're casting with pure lead they should 'bump up' to fill the rifling. Of course you can cast some, then beagle the mould, cast some more, and compare the results. Perhaps you should use the beagled boolits when the barrel is clean, and once it starts fouling you could switch to the normally cast ones. That's the nice thing about beagling a mould, not only can you remove the tape, but you can beagle it again after removing the tape, so you should always be able to cast the 2 sizes of boolit.

- MikeS

Want to checkout my feedback? It's here:

http://www.castboolits.gunloads.com/...d.php?t=136410

I've shot these in my 54 renegade. They are supposed to go down the bore fairly tight. The REAL means Rifling Engraved At Loading. So, they should not drop down the bore. They are tough to load in my rifle. But, they shoot well. The only issue I have with them is they don't hold much lube. Beagling will probably do the trick. Good luck.

Ditto.

"Rifling Engraved At Loading" should offer resisitance to engrave the bands with the rifling. If they drop in, they are not engraving. They can be a bit tough to start and seat with pure lead but I watched a guy beat one into the muzzle one day that he had cast from wheel weights.

I tried them (with pure lead) and they were more work than a tightly patched round ball and did not shoot as accurately in my particular rifle so I stuck with the round balls.

thanks guys. Super helpful. Finally! I have some beagled bullets, no lube yet. Will try when I can. Soon as I can find some local beeswax for a test.

Some people say they drop too small but I believe in actuality they are not getting the mould hot enough and not getting good fillout of the bands. They should be dropping .517 at the top band. They are NOT suppose to be loose, that is the minies.

Aim small, miss small!

you guys rock. this bullet actually shoots now. two of three in the steels (im confident I can get 100% now). Alls it took was beagling, halving the powder used, and a new lube.

No swabbing either though I only shot 15 or so rounds. Doesn't get better than that.

I just bought 300 sabots for use with gascheck bullets without the gascheck. Turns out I wasted my money on that little expenditure! I'm happy to say that though.

+1. Both my REAL moulds drop the bullets with the front band at .515. Get the mould hot and keep it hot. I also use a 40-1 lead - tin alloy and ladle pour (Lyman technique) the alloy to get it into the mould before the mould and alloy cool too much. A bottom pour may not get the alloy into the mould fast enough.

Larry Gibson

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |