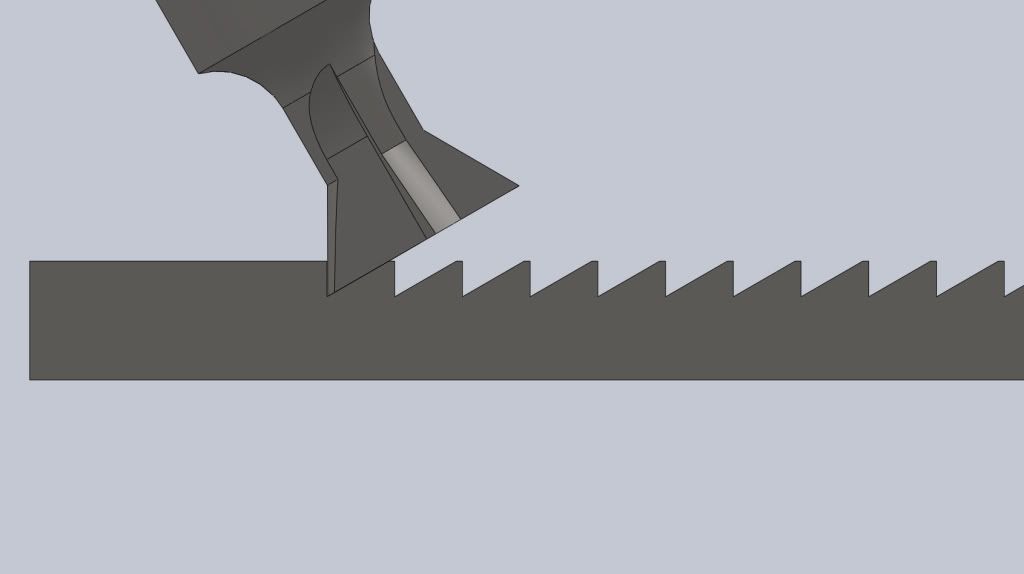

A few months ago I purchased a trunk load of assorted stuff from the son of a deceased gunsmith. Among the many treasures was a 1911 slide, a couple of barrels and assorted other parts. It looks like he was going to make a custom 1911 from it by sanding off the maker's name from the side of the slide. In doing so, he messed up the cocking serrations on one side. Maybe he had a plan of some kind to repair/replace them, but it was never finished. My question is, how could I go about repairing this so it wouldn't so unsightly. I don't want to remove any more material as I think it would be to thin. Would silver solder work to fill in these serrations, smooth it out and have them re-cut? I've worked with silver solder in the past making musical instrument parts and my plans are to DuraCoat the 1911 when it's finished, so I think it would be a virtually invisible repair. Would this be a viable and durable repair?

Thanks,

Greg

|

|

|

Reply With Quote

Reply With Quote

"Those who would give up essential liberty to purchase a little temporary safety deserve neither liberty nor safety".

"Those who would give up essential liberty to purchase a little temporary safety deserve neither liberty nor safety".