We have had a number of threads in which we discussed what it takes to make a chamber that is 'friendly' to paper patched bullets...as friendly as the old original chambers that were used by the Sharps factory.

Those chambers assumed the bullet would be patched to bore dimension, and were sized accordingly. But, they also provided a low-angle transition from the case to the 'throat'...and on into the rifling.

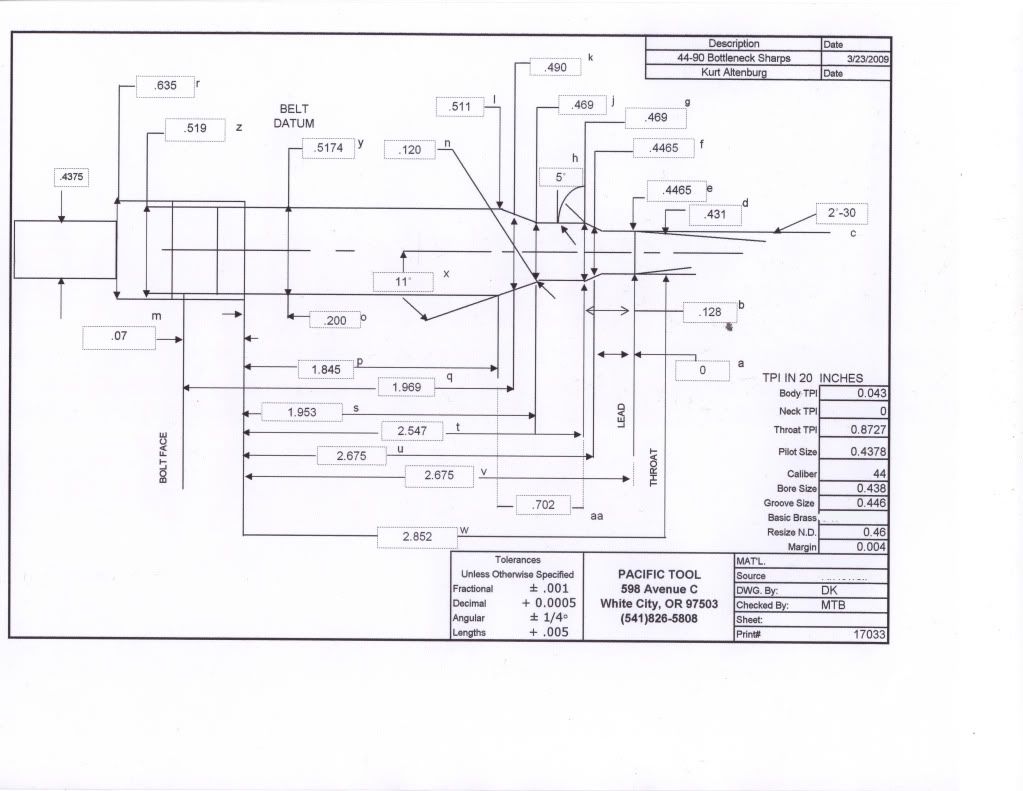

Yes, the old chambers can be duplicated in a newly cut barrel, but the threads examined modifications to SAMMI chambers intended for grease grooved bullets...which would remove some of their unfriendliness to the paper. Basically, the fix was to shave the 45 degree chamber step (transition at the case mouth) down to a gentler angle. 15 degrees and below have been considered, with five to seven degrees coming close to being ideal for patched-to-bore bullets.

I saw a recent reference to the 45 degree chamber step in a Pedersoli rifle being referred to as the 'leade'. Knowing that the actual leade angle in a Pedersoli is not 45 degrees, I opened an old email I have from Dick Trenk wherein he describes the current Pedersoli chamber...and it's 'throat'.

That's the first time I ever noticed that Pedersoli 'chamber steps' are NOT 45 degree angles. Instead, they are much closer to 10 degrees.

10 degrees, 12 minutes, and 14 seconds to be exact.

Wishing I could visualize such a topography, I'm hoping Tom Meyers can help out with one of his excellent drawings.

I have sent him the particulars...along with a rendering of the PGT bullet (for those interested in the 'correct' GG bullet for Pedersoli guns) and a Money bullet patched to groove diameter (because that's what I do, and it's my project).

Hoping he has time to draw this up...

CM

|

|

|

Reply With Quote

Reply With Quote

Matching the bullet to the bore is a pretty stright forward process, in my opinion, if one is willing to wipe between shots you can shoot exceptional accuracy. I posted before that you can have the very best quailty barrels, yet if its a lousy chamber you wont shoot well. Very few people know how to control fouling well, either, last match I attended was proof enough for me. One good friend was having leading issues with his 45-110 Shiloh and shooting GG bullets, Too much wipping!!! I had him cut back to one single damp patch, (same I was using) for my GG loads on Sunday.

Matching the bullet to the bore is a pretty stright forward process, in my opinion, if one is willing to wipe between shots you can shoot exceptional accuracy. I posted before that you can have the very best quailty barrels, yet if its a lousy chamber you wont shoot well. Very few people know how to control fouling well, either, last match I attended was proof enough for me. One good friend was having leading issues with his 45-110 Shiloh and shooting GG bullets, Too much wipping!!! I had him cut back to one single damp patch, (same I was using) for my GG loads on Sunday.