So here I was bumming around school and I found some big 'ole hunks of alluminum. I'm talking big here, 12"x12"x60". Asked the machine tool instructor here what those were for and he said they had been here for the better part of 6 years and nobody had ever touched them.

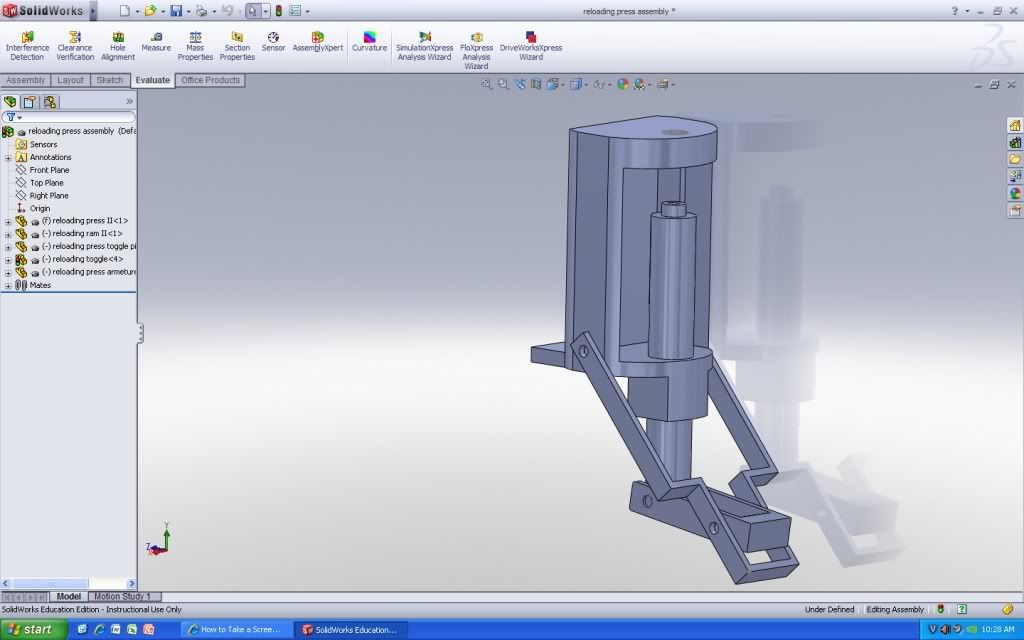

Ran next door to the computer lab and drew up some plans to build a simple reloading press on solidworks that would be capable of performing 99% of my reloading needs. Not that I really "need" another press by any means (I think I have 6 or 7 on my bench at home), but It would be pretty cool to have one I totally designed and built myself. Today I'm just going to true up the block and fine tune my design but I figured I'd try and chronicle my build here because somebody would find it interesting.

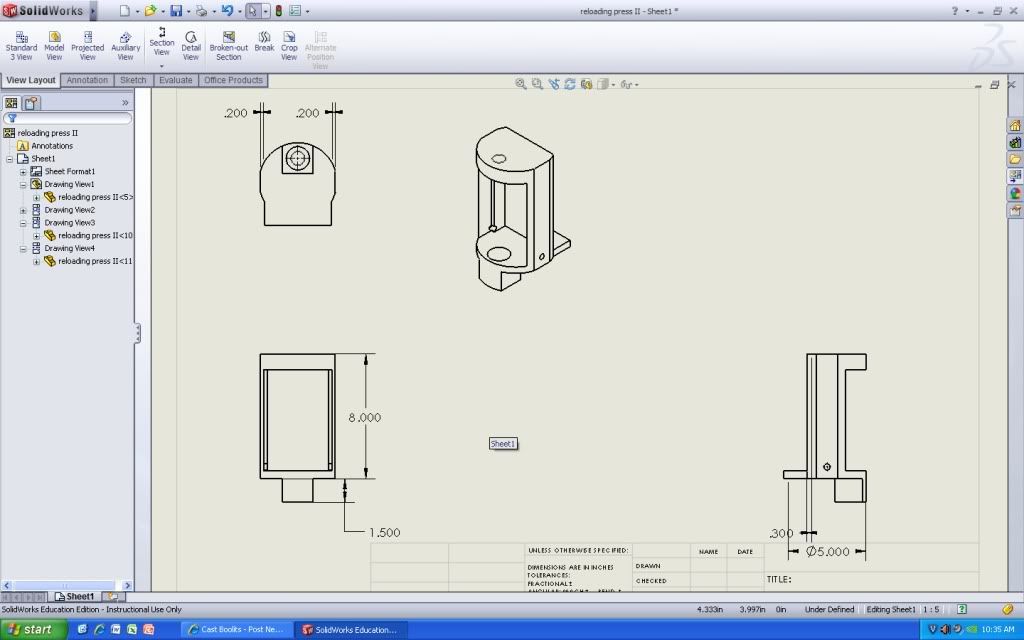

Decided to make a simple design that is enclosed on 3 sides and have plenty of strength to resize most cases. The press will stand 8" on the bench, and be about 4.8" wide. I'll try and attatch a few screen shots, but I'm not too computer savvy so we will see how it goes.

|

|

|

Reply With Quote

Reply With Quote

I am drawn to it for some reason.

I am drawn to it for some reason.