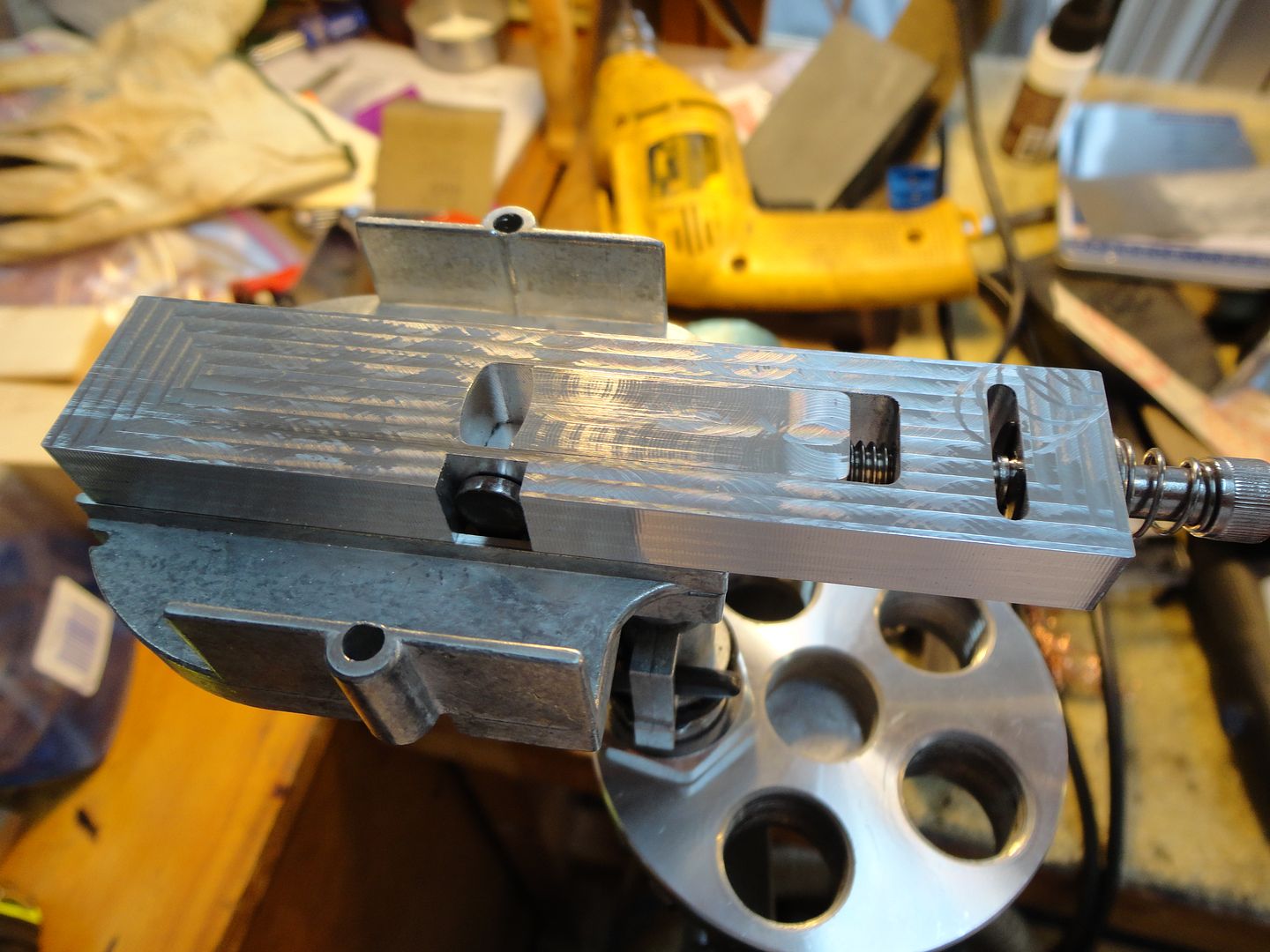

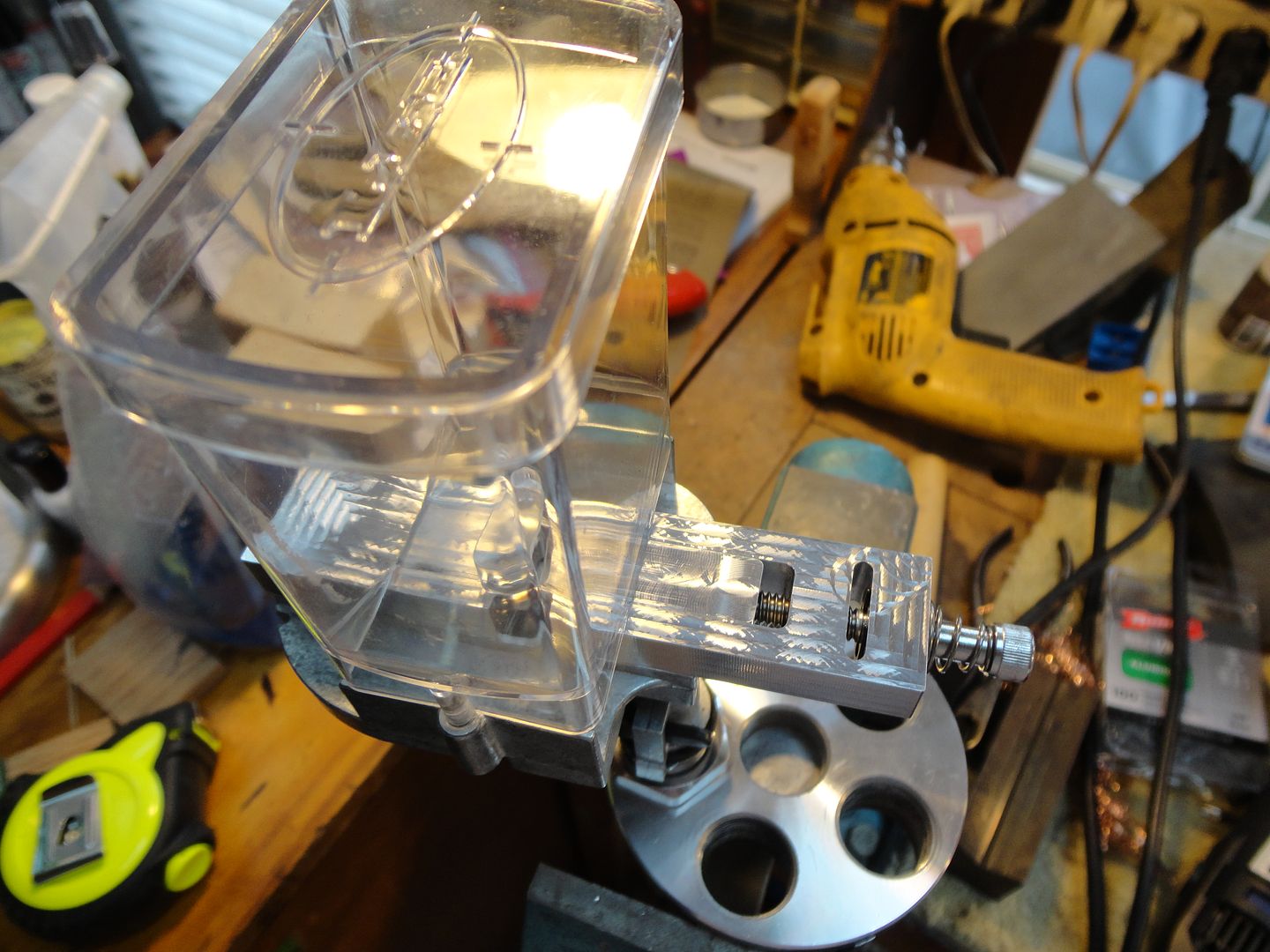

I had similar problems, and bought a powder baffle from UniqueTek ( http://uniquetek.com/product/T1278) reckoning it may be worth the ten dollars, if it worked. I dropped forty successive H110 charges, and quite frankly noted there is an improvement -- but, for me, not where I wanted it. Sooo, I bought a powder weight off eBay ( https://www.ebay.com/itm/143130588009 ) which actually seemed to lower consistency a tad -- as proved by another 40 test drops. My last improvement attempt what two-fold, where I rub-a-dub-dubbed with a dryer sheet; and, drilled a small hole in the powder baffle for a 4-40 nut and bolt, to which I attached a length of thin copper wire -- the other end fastened to my (electrically grounded) metal bench leg. Bion, this showed improvement, but not what I wished for. So... what I have been doing since is what I saw another fellow do in a YouTube I viewed while researching the problem. He had (as I now have) his Determinator scale on bench to the left of the Dillon press, and after the case is primed, and rotated to powder station, the now-primed case is put on the scales and zeroed. After powder dump, it is again removed and placed on scales which now indicates exactly how much powder was dumped. If the amount meets my criteria, I put the case back in and continue the loading sequence. If not, I put it in a loading block for either a later re-try on the press, or, what I've been doing mostly is using a trickler.

Yes -- kind of a pia -- but I, too, have not found an ideal solution. Oh -- re "rejects" -- I only (only?) find two or three out of 40 which are 0.2 grains or more "off" -- my criteria.

My experience...

geo

|

|

|

Reply With Quote

Reply With Quote

DougGuy

DougGuy