I've owned my Lee Ergo Primer seating tool for about 2 months now and have seated large rifle and small pistol primers with my tool. The tool seems plenty robust.

The small tray seems to feed better than the large one , but the small tray still jams quite often.

The large tray didn't work very well at all. Maybe I wasn't using the right " tilt " continuously ? ?

At any rate, I got frustrated and got out my Dremel tool with my cut off tool and did some modifying to the primer seating tool this morning.

I always thought that the Old Mequon primer seater tool was so simple and fool proof.

You'd simply insert a single primer , close the handle and you had a seated primer. I liked that simplicity and decided to copy that engineering concept today with the Lee Ergo.

At any rate ( right or wrong ), I decided today to give up the feature of the primer auto - feed, in favor of seating a single primer at a time.

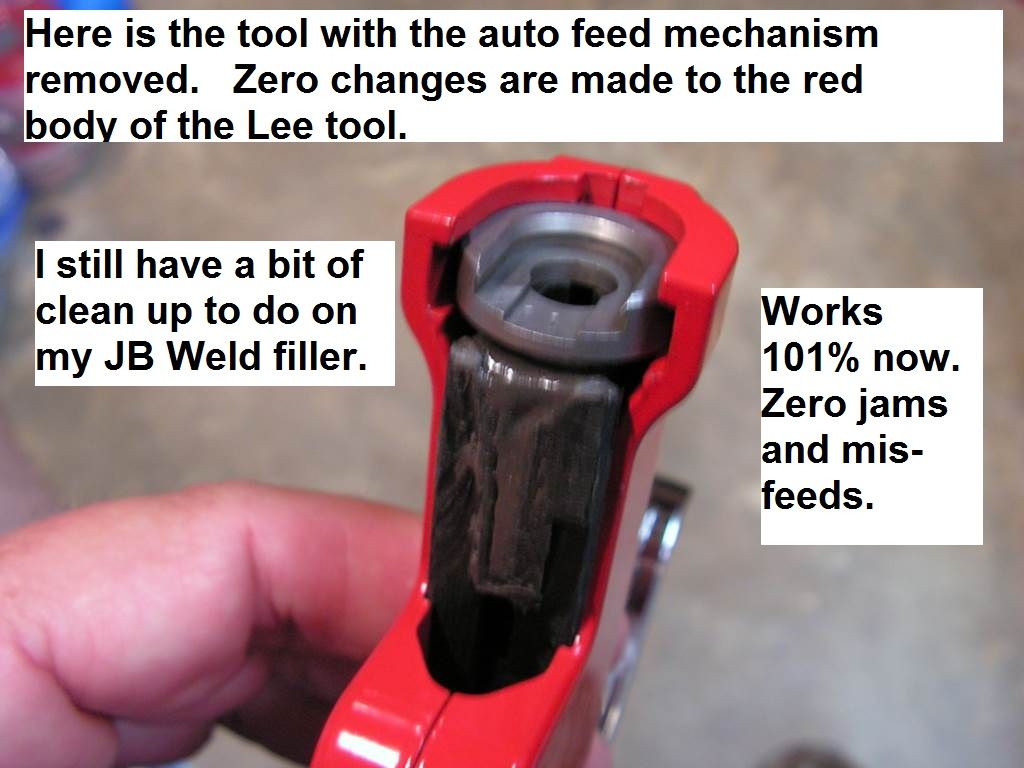

The conversion consist of simply removing the auto feed mechanism without harming the square nylon carrier for the alignment and up and down travel of the primer seating piston. That part of things can't be changed.

Once that is done, there is a bit of " fill in " with 5 minute quick set JB Weld. There is a channel that the auto fill would use to gravity feed primers to the piston for seating of the primers , that channel needs to be filled completely with JB Weld. Be certain that the " bore " that the primer seating pistol travels in stays clean and free of any of the JB Weld.

A little clean up and now I've got a priming tool that won't jam. Granted it may be a bit slower, but considering all the time I spent clearing jams, hunting primers that had fallen on the floor, etc. I'm not too certain that I can't prime 50 cases just about as quick .

One thing is absolutely certain, I've dramatically reduced the " frustration factor " on my priming tool.

As far as I'm concerned, there is something to be said about reliability. You either have it or you don't ....there is zero room in between the two. This " thing " wasn't even close to being reliable yesterday , .......now it is ! From my perspective, I've made some good progress today.

I have a portable reloading kit. This tool ( in its modified form ) will serve as an excellent priming tool for my portable reloading kit.

If at any time in the future I want to return to the auto feed ( and I seriously doubt that I ever will ) , since I made no modifications at all to the red steel handle , I can simply contact Lee and have a new tray / feed mechanism shipped and I'm right back where I started.

Ben

Here it is with all the surplus JB Weld hardened and filed off smooth, then touched up with some gloss black enamel and an artist brush.

|

|

|

Reply With Quote

Reply With Quote