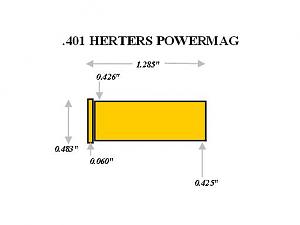

I was looking at a 401 Herter's Powermag cartridge, and then I started thinking. I wonder why there is no 10mm Auto Rim.

I noticed that 401 Powermag was pretty close already, and it can be formed from 41 Magnum brass, or even 30-30 Winchester brass. (Though if made form 30-30 brass it has slightly less internal case capacity)

So why couldn't I make some brass like this to fit in my Smith 610 revolver and quit being married to moon clips?

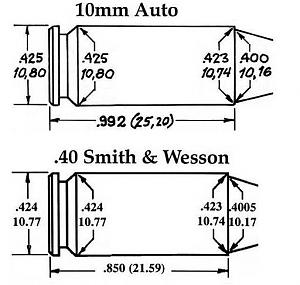

I started out looking at cartridge specs for the 401 Powermag, 41 Magnum, 30-30 Winchester, and the 10mm automatic. Soon I was measuring cases, trying stuff, and the wheels started turning.

It looks like quite a squeeze to get 41 Magnum down (about .009) but the rim and internal case capacity look promising. I have heard of folks doing this with no shell holder, or a shaved shell holder to size 41 mag all the way down to the rim, and then using a hammer and punch to get the 41 Magnum brass out of a full length size die to form 401 Powermag.

Using 30-30 Winchester brass seemed easier than sizing 41 mag brass down that far somehow. I also have a lot more 30-30 brass than 41 Magnum, so that helped sway the decision. I snagged a 30-30 case, shell holder, and with my trusty RCBS case trimmer, I shortened a 30-30 case down to .992

I de-burred the case and did some light inside neck reaming. I probably should have annealed before case flaring and seating as well. I did some revolver cylinder mock ups using the new case.

The first little speed bump I ran into was putting a large pistol primer into a case that already uses large rifle primers.

I removed the spent 30-30 large rifle primer, pulled the anvil out of the cup, and knocked the firing pin dent out of the primer with a small punch.

I reseated this dummy anvil-less primer in the case, and tested my firing pin hit for strike and protrusion. The 610 put a dent in the deactivated rifle primer, so the whole thing seemed feasible so far.

Then, I seated a Win large pistol primer in the 30-30 case... Oops forgot large rifle primers are a tad taller than large pistol primers. I noticed .120 and .130 difference between the two. So a large pistol primer seats in about .010 too deep in the rifle case. I guess that's always better than sticking out, but I didn't like it. It seemed like I was already on the minus side of things for firing pin protrusion from not using moon clips.

So I pressed the primer out, and made a very small thin copper shim washer. I pressed the shim into the primer pocket and reseated a pistol primer flush. Perhaps this is why 41 Magnum PISTOL brass was a more popular choice as a parent case for the 401 Powermag.

Well anyways, I got this far with it.

In the pictures the case is not flared yet, and I just have an upside down 10mm FMJ stuck in the case for perspective. (not seated or crimped) It seems doable so far.

I still need to measure the internal capacity of the case to get an idea where I will be at for a load. Assuming the new case has the same capacity at least as 40 s&w and not less, I was planning on starting with a light 40 s&w load, and seating to long 10mm OAL's to keep pressure on the safe side of things.

I was wondering if anyone else has ever tried something like this? Since I had never seen 10mm Auto Rim brass before.

- Bullwolf

|

|

|

Reply With Quote

Reply With Quote