I realize for the people who have been forum members here for a long time that this information isn't going to be very interesting to you.

However, we are adding new members at a rapid rate now. Many will be on a budget and trying to cast good bullets with economical Lee double cav. and single cav. molds.

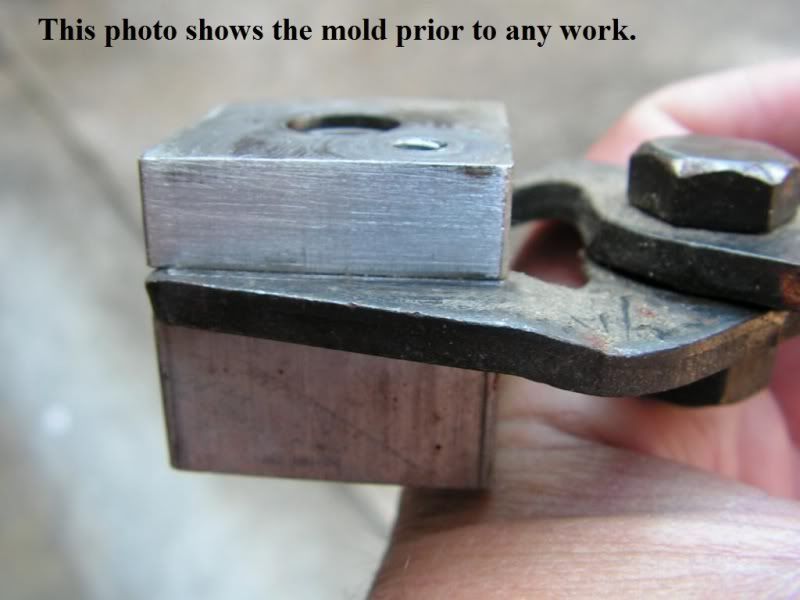

I had a 41 Mag. single cav. mold that was over 25 yrs. old. The sprue plate screw would not stay tight ( I know that isn't new is it ? ). I decided to do my standard modification to this particular mold and get my dig. camera out and shoot a few photos that might make it educational for a " newcomer " that has never seen the process before.

As many of you are aware, Lee often ships molds that have the sprue plate screw so tight that within just a few opening and closing of the blocks, you've got damaged, galled blocks.

The sprue plate is far too tight on many of the Lee molds and there was no lubrication ( need to use Bullplate ).

All this combines to render the molds un serviceable in a fairly short period of time.

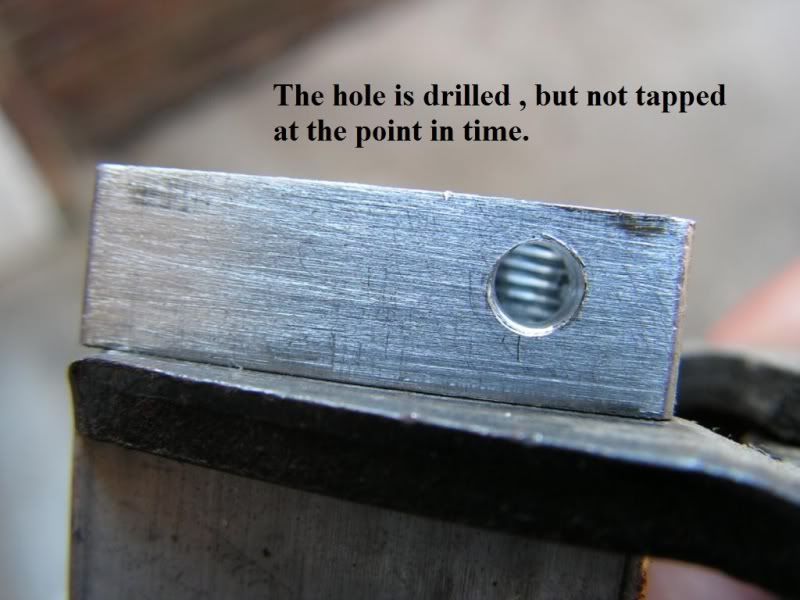

By removing the screw plate hold down screw and removing the sprue plate and drilling and tapping a 10-24 threaded hole, this problem can be fixed permanently. This allows you to put any amount of sprue plate tension on the plate that you need and then lock the screw down just as you would a Lyman , RCBS, or SAECO mold.

Here are photos showing how I do this modification. I hope this is helpful to

many of you young casters :

It is very possible that there are other sizes of taps and drill bits to do this job with.

This size works well for me however :

Here is a poor quality movie ( took the movie with my cell phone ) that will let you see the end result of this work.

Thanks,

Ben

http://www.youtube.com/watch?v=1WAnEcgdFJk

|

|

|

Reply With Quote

Reply With Quote