50 Yard Targets.JPG

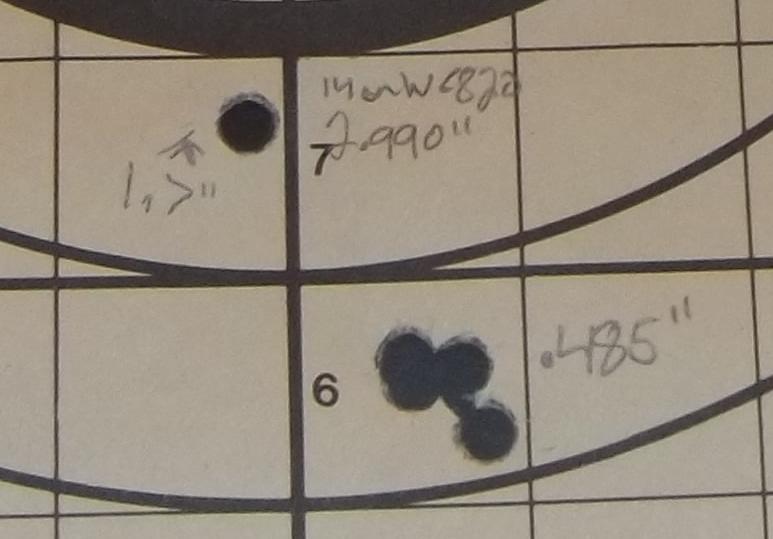

Well I'm back from a day at the range. Even though it was 101 degrees I'm not going to blame the weather; I shot more poorly than usual, but that's OK because I shot both types of bullets equally as bad so the comparisons are valid. I shot several groups at 50 yards with both .309" sized bullets and .312" sized bullets from two different rifles. One is a 94 Brazilian Mauser with a 30 caliber barrel that I turned from a hammer forged blank and chambered with a Lapua reamer. The other is a 93 Mauser with a barrel that I got from Numrich. Here are the average groups sizes for these rifles:

1894 Brazilian Mauser - 50 yards - .309" bullets -1.56", .312" bullets - 1.84"

1893 Mauser - 50 yards - .309" bullets - 3.75", .312" bullets - 2.75"

Not surprisingly, the hammer forged barrel shot better than the Numrich barrel. After firing eight groups at 50 yards the results showed that the 94 Mauser shot better than the 93 Mauser. The 93 Mauser shot groups an average of 1" smaller using the .312" bullets, but the 94 Mauser shot tighter groups over all. The difference in group size between .309" and .312" with the 94 Mauser was only about a quarter inch, and this could well have been caused by the shooter as much as the ammo.

At the 100 yard range I really stunk. I was shooting the 94 Mauser and I only shot one group with each lot of bullets. I'm ashamed to say that I shot both groups at around 4.5" in diameter. There was no difference in the accuracy between the .309" bullets and the .312" bullets at this range. In spite of my bad shooting today the results seem to suggest that getting better accuracy by increasing the driving band diameter relies entirely on the gun that you're shooting. I know that this test was a limited data pool, and is semi-inconclusive, but in this shoot one rifle shot better with the larger bullets, and the other didn't. I would have to guess that individual shooters will have to determine which diameter works best in their particular firearm.

|

|

|

Reply With Quote

Reply With Quote