I use an old production, Lee tl sizer die nominally stamped .430, bought new years ago_

cast bullets exit sized at .428.

is it normal or a lemon?

|

|

|

I use an old production, Lee tl sizer die nominally stamped .430, bought new years ago_

cast bullets exit sized at .428.

is it normal or a lemon?

Food is overrated. A nice rifle is way more important.

Rob

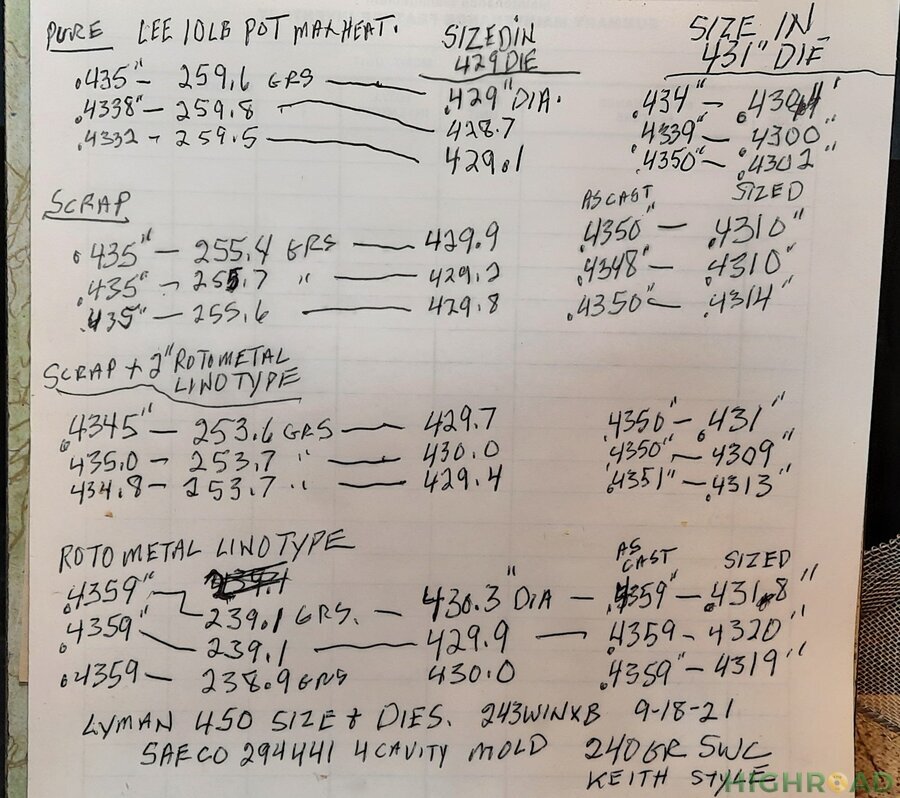

.428" is smaller then normal. The alloy used can make a difference after sizing. The harder the alloy, the more spring back. Larger bullets.

But its not going to spring back .002"

I would first verify your calipers are accurate and correct.

If that die is stamped. 430 and spitting them out 428, you should then check if there is oxide on the ID. Lastly, you have 2 options, pitch it, or hone it out to 430.

400-600 grit paper on a dowel rod attached to a drill will work, take your time and test the size frequently.

Sent from my SM-A526U using Tapatalk

.428 is good for 44-40!

A member here might be interested in it!

verifying the accuracy of my caliper first makes sense,

but could it possibly happen that if the bullets are manageable but perhaps not yet completely cooled inside they undergo a sizing compression which, when really cold, are then of a smaller diameter?

(in this case, my alloy is 20:1 lead/pewter)

Last edited by wilecoyote; 05-25-2023 at 08:22 AM. Reason: alloy

Food is overrated. A nice rifle is way more important.

Rob

It's a fair question, but I'm not sure what you consider warm. If you are casting and then water dropping, they will become completely water temp within 3-5 seconds.

If air cooling onto a towel, and you are able to handle them by hand. They are less than 90 degrees F. In this case, they are stable solids and all deformation is permanent. There wouldn't be any measureable elastic deformation.

Pure lead would give you the best measurement of the die size

Sent from my SM-A526U using Tapatalk

pure lead shrinks the most however... so wait till it is cool to size.

Rotometal pewter has 98% Tin, 1.5% Bismuth, 0.5% Copper. To make a larger bullets, antimony is needed.

...no antimony added, in my last casting session...

thanks for all the opinions given.

I hope it's a caliber issue. because in any case inserting some sized and dry cast in the cylinder of the 29 shows a slight but constant friction at the exit, and this is probably the question that matters most, as ultimate goal.

Food is overrated. A nice rifle is way more important.

Rob

If the die is truly sizing to the wrong size call Lee and they will send you a new die! Call do not email!

Long, Wide, Deep, and Without Hesitation!

Food is overrated. A nice rifle is way more important.

Rob

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |