follow up:

found that if a bullet stops right at the top of the chute the next one down will jam. Sounds like a 'no biggie' until you realize the bullet in the H die is getting swaged into the holes of that die. Turns out you have to take the die out and clear the lead from the holes. Not a big job but it is required to get the operation back on track.

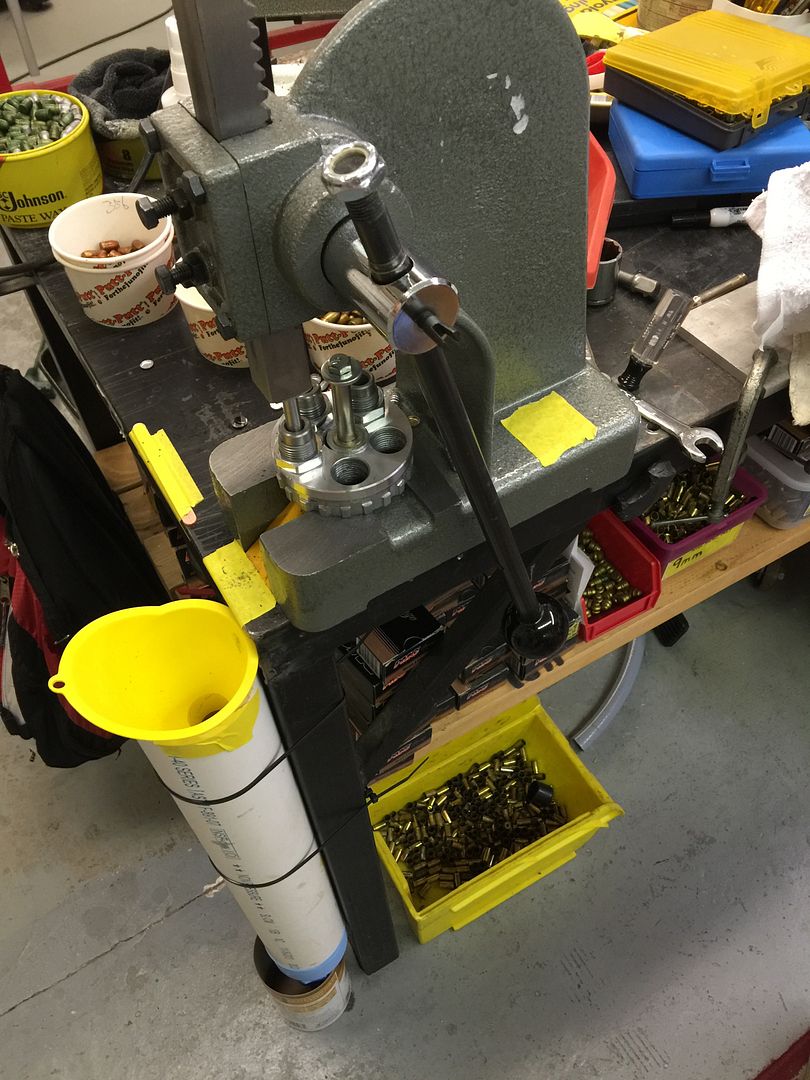

Other than that learning experience I'm enjoying sizing and watching the bullets take a trip down the tube to the catch box.

|

|

|

Reply With Quote

Reply With Quote