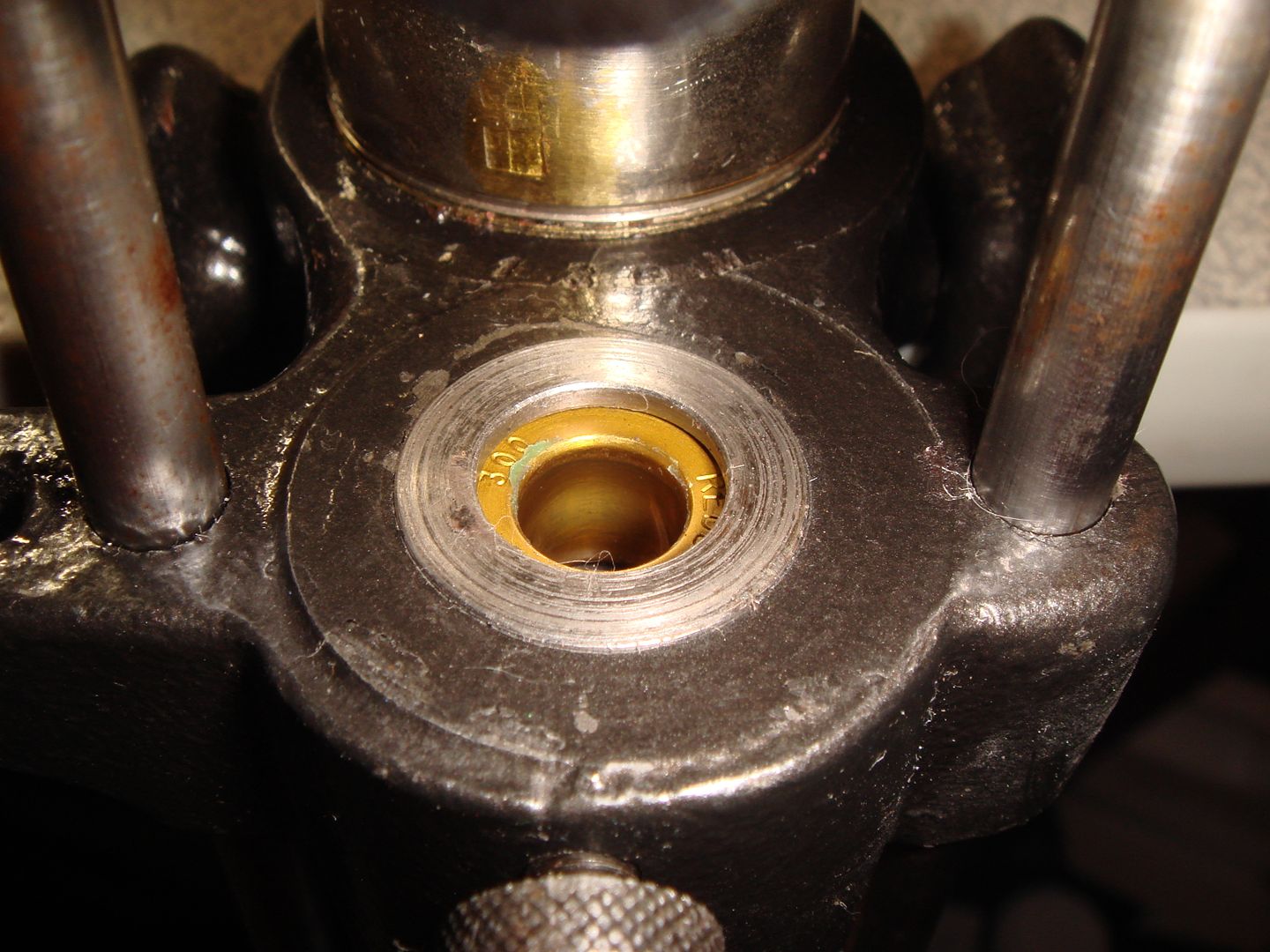

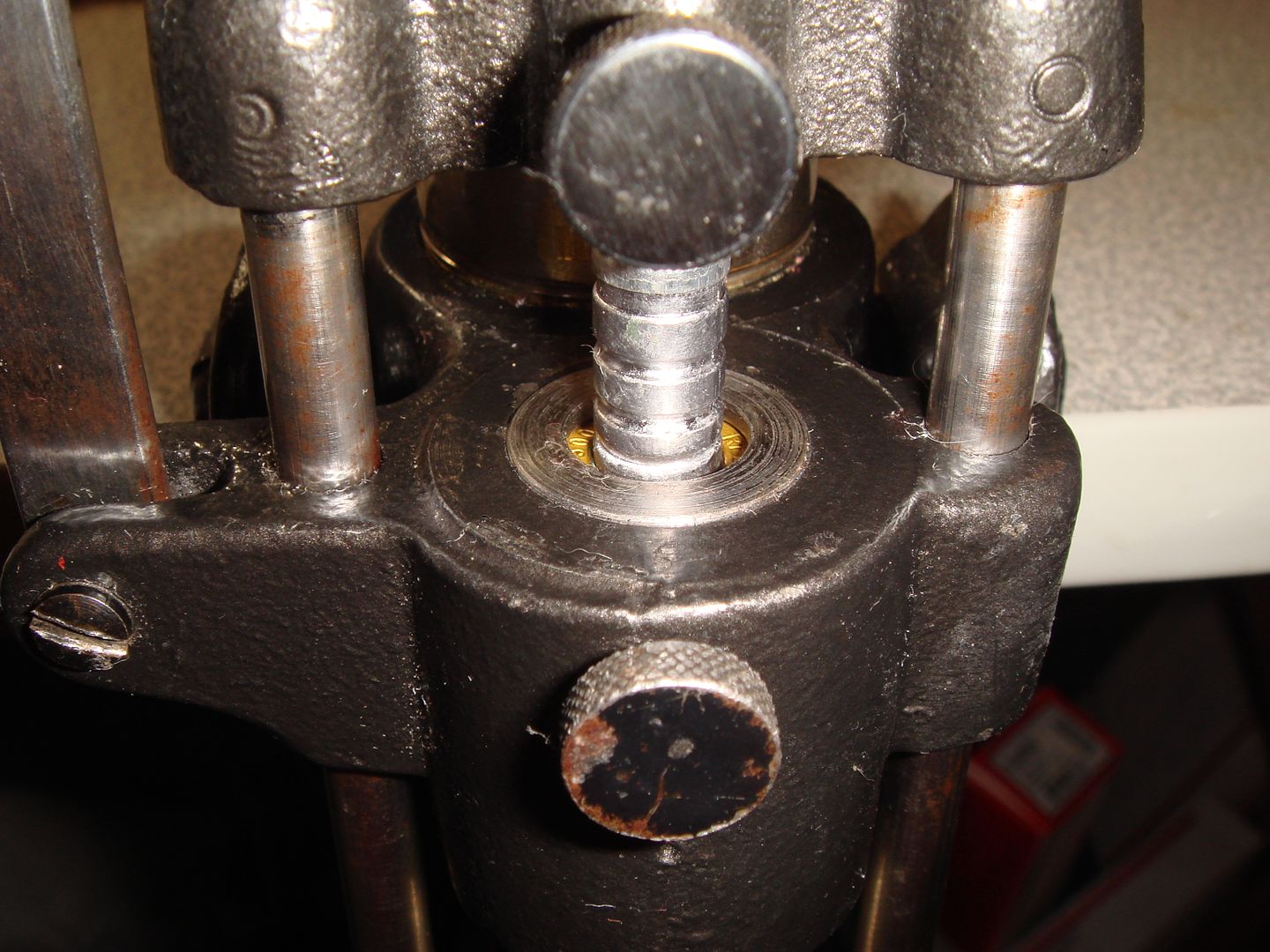

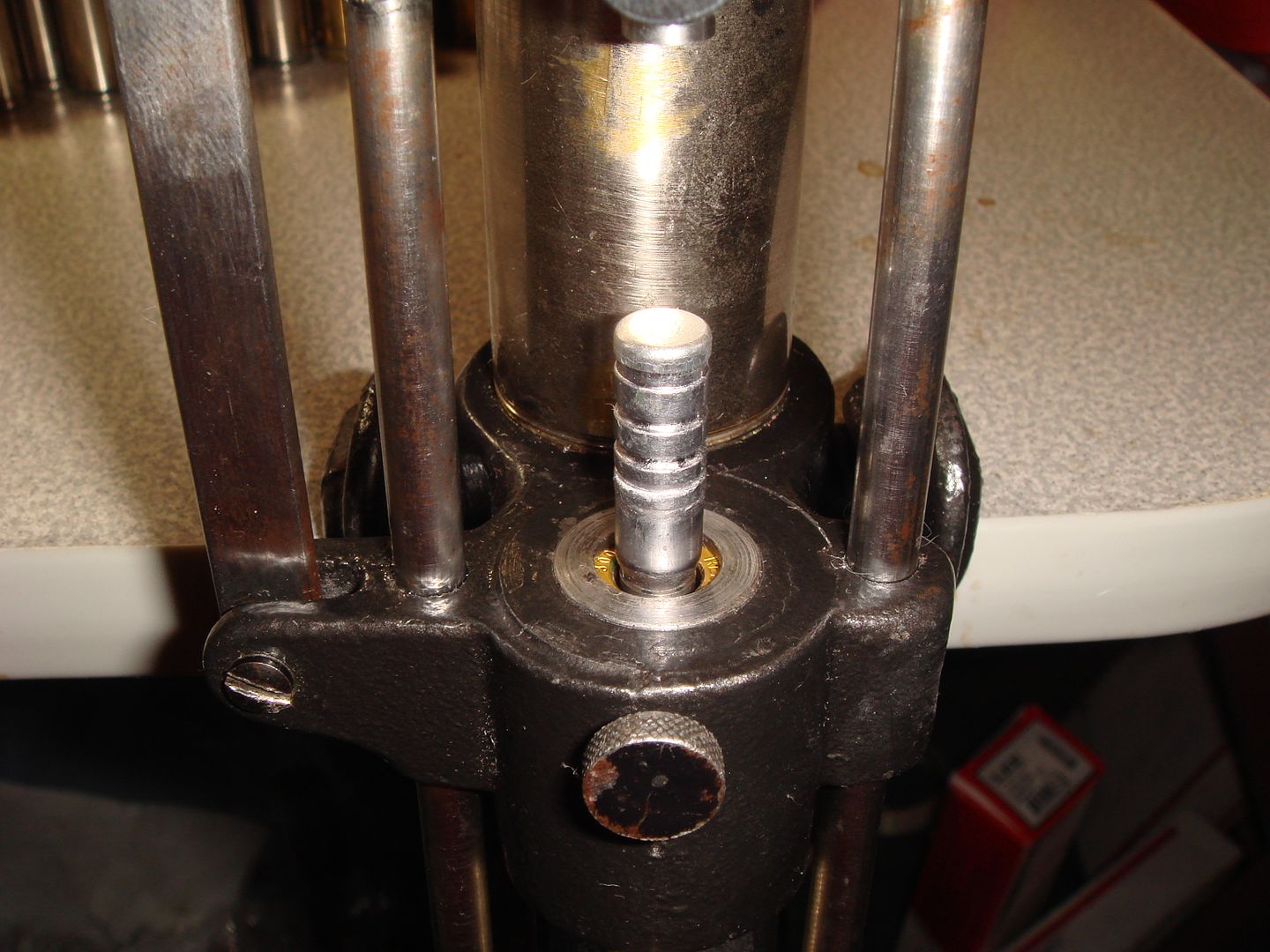

Bore riding bullets are used by most of us to get the most accuracy from our rifles. I'm wondering how the various coatings effect the fit of our bullets nose to our rifling. With most of the coatings we are adding .004 to .005 diameter to what is a critical section of our bullets. Do any of you have any thoughts on this topic?

Nighthunter

|

|

|

Reply With Quote

Reply With Quote