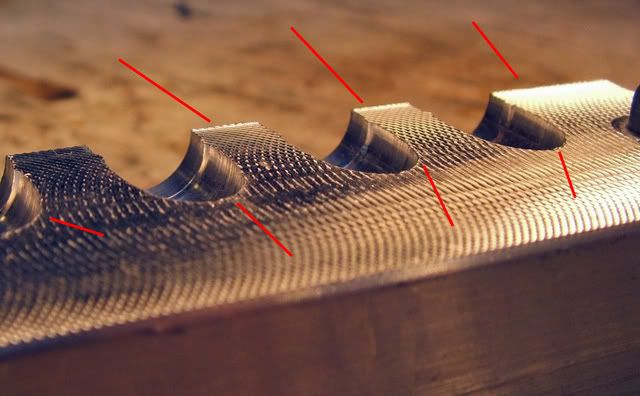

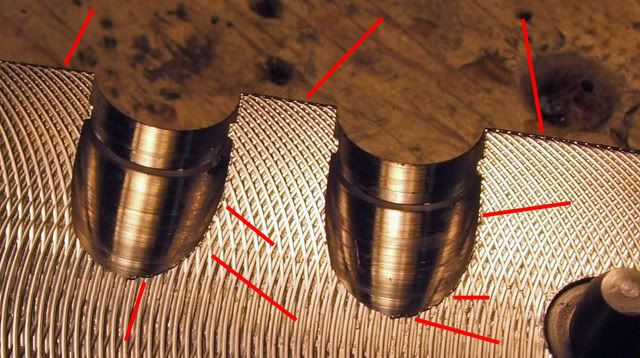

Thought I would post some pictures of a new LEE six holer I just received from Midway USA.

Only took me a few minutes to get the mold cleaned up and it dropped bullets like a dream after warming it up a bit.

Open the handles and say "Boo", and they fall out.

|

|

|

Reply With Quote

Reply With Quote