I recently purchased a used mold here on the forum. The individual that " gave it to me " said that it was damaged and he didn't feel good about selling it. He said I could have it if I'd pay the postage to get it shipped ( $5.20 ). I felt it was worth trying.

The mold is a Lachmiller 2 cav. 311170 RN ( basically a clone of the Lyman 311291) .

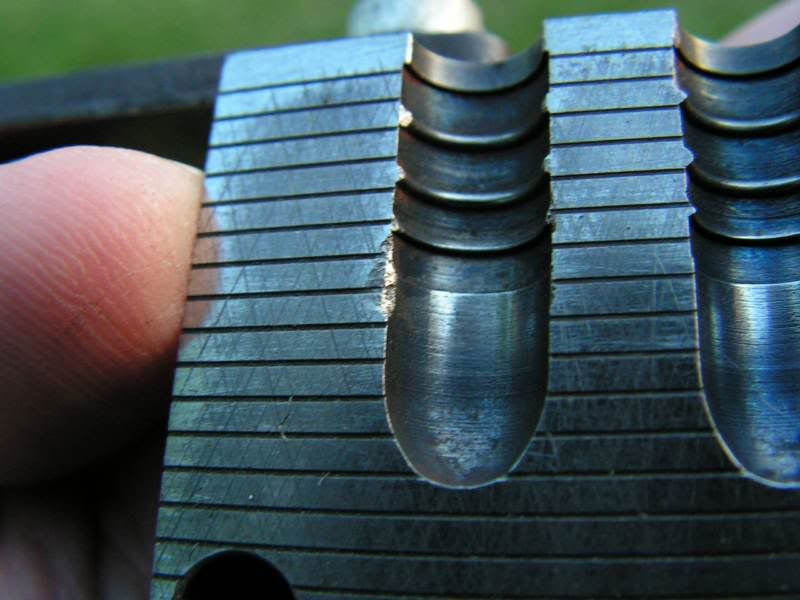

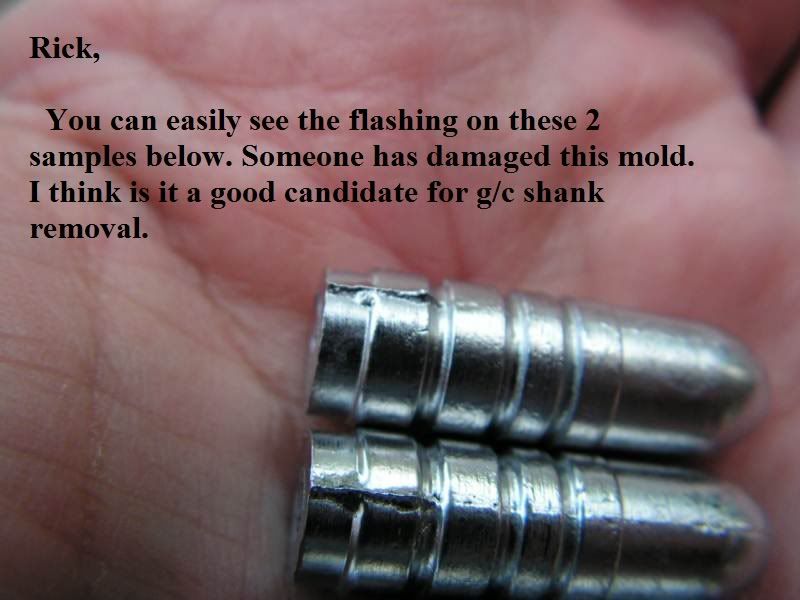

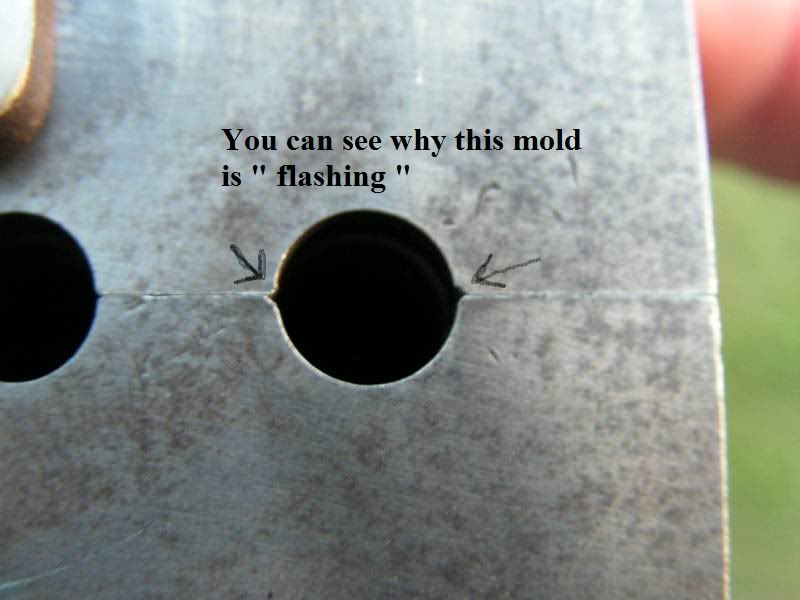

Someone had damaged the interior edges of the one and only usable cavity of the blocks. The cavity closest to the mold handle hinge pin was damaged beyond repair.

I tried to cast with it ( in the front cav. ) and got bad " finning ".

I decided it would be a good candidate for plain basing and the removal of the g/c shank which would clean up a good bit of the damaged area of the mold. I thought about sending it to Buckshot or Eric, but I decided to give it a try myself. My thoughts were..." I've only got $5.20 in this mold, I don't have a whole lot to lose."

I took a 5/16 " HSS drill bit was is super sharp. It mikes around .312 ". I put the mold blocks into a set of clamps and set everything on the bed of my drill press. I spent about 15 minutes checking to be 101% certain that the drill bit was going to enter the cavity as near perpendicular as I could make it. Then I drilled out the g/c shank.

Here are the results :

|

|

|

Reply With Quote

Reply With Quote