I have no idea what the used machinery situation is in Golden meadow La. Cajun Country so this is just me listing stuff.

5k is goodly sum for a hobby lathe, and will get you a "real" machine.

First off il say the low dollar imports, IE Enco, Jet, Grizzly and harbour freight and so forth and so on, can be all painted with the same brush in that they are low grade hobbiest ****. Included are some (but not all) the reasons these lathes are not used in real shops.

1. Bad electrics if they are anything more complex then a self contained motor turning a belt, those ultra safe safety lock switches are the first thing to break.

1. Handwheels are cheap and break, dials are cheap, apron gears can and do strip.

1. Some I've seen have gears so badly cut in the gear head models that it was almost impossible to change speeds.

I could go on but il say that all the said brands serve their owners well, if not pushed and cared for as well as used lightly. These machines are HOBBIEST GRADE, just because it has a sticker that says "Pro Model" doesn't mean thats the case. There's a reason no serious machine shop uses these things. There is no difference in buying one of these "lathes" and purchasing a 15 dollar 180 peice combo wrench set-----not for serious use.

But your in luck, as you have a good budget for the lathe (im assuming 5 k includes some tooling youl need), unfortunately its a little low to buy new "real grade" but no big deal.

So heres some good used brands in that size to look for used. Reason I advocate buying used is because 5 grand new will get you a junker that you wont be satisfied having put 5000 hard earned dollars into. Anyways heres a partial list.

Kingston, Mori Seki, Mazak, colchester (parts are expensive), clausing, Monarch, Boxford and the list goes on and on and all it takes is a little internet searching.

Things to looks for.

Simplicity: The old style southbend lathes used cone pulleys and belts for speed changes, while you may not like this archaic method this system is very simple and relatively cheap to fix. Blow a bushing or ruin a gear somewhere in the train of a gear head, and get ready for a headache and you can pay the big bills to reapir it just like a real machine shop does

.

Change gear machines are tedious: Want to slow down a cut? Speed it up for a facing cut? Set up a threading train wrong? Well get ready to swing open that cover and juggle 4-5 gears, and wrench (possibly 2) and an oil can to change the gear train.

Consider something slightly larger if it comes your way: Bigger machines are not popular with hobbiests, and the size you specify is just touching the end of there comfort zone, because anything bigger may require machinery movers and some slight work to get in their toy room to tinker on, thus making them MUCH cheaper.

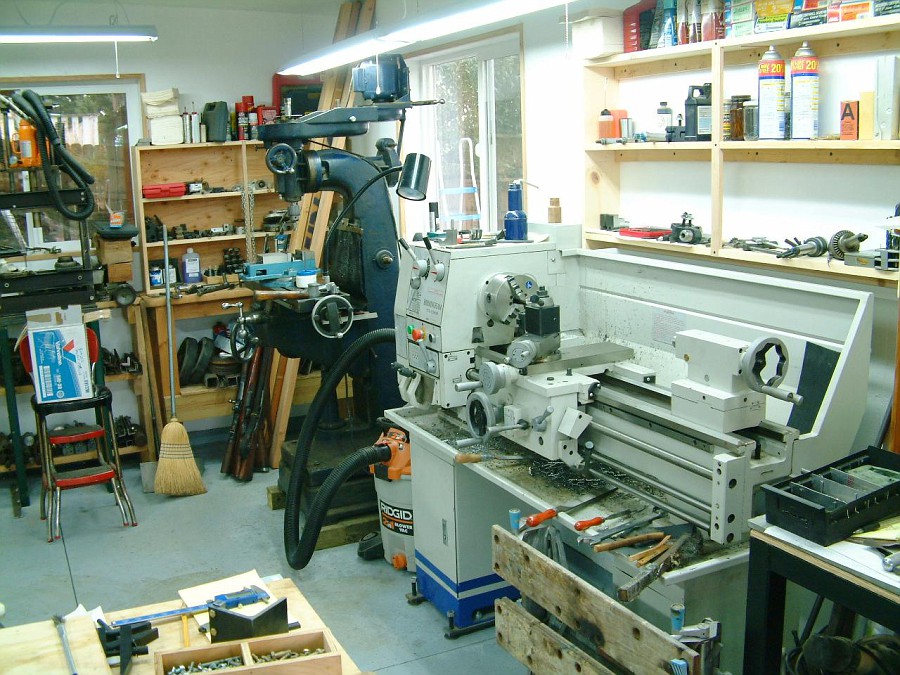

Paint condition is meaningless: Machinery.........like women are much more interesting the dirtier they are and the less duds they are wearing. If you buy a used "real" machine, it will likely be FILTHY its been used in a dirty shop that demands production and doesn't allow more then a casual sweeping and a rub down with a rag once in awhile.

Be patients if you go this route: you could have an Enco lathe in a week at your demand if you wanted it, but it may not outlast you, and it certainly will be fit only for the junk heap in 10+ years if you use it in any capacity.

So short version:

1. Buy a used professional grade and name brand machine

2. Must have quick change gearbox

3. Bigger used lathes, are usually cheaper to purchase.

4. Pic a lathe thats simple to fix (example: the old southbend or sheldon style lathe) usually a belt drive with back gears.

5. don't write off a machine because its dirty

6. Don't buy the first one you see, be patient.

Reply With Quote

Reply With Quote

.

.