Recieved my first RG4 design mold in the Smokin' Hot 32/327 design today which I was really pushing hard to get and despite the 105 heat index today I cranked up the casting pot and gave her a go. Boiled the mold on the stove in pot for a while to get any oil out of it and got it nice and hot by setting it on the RCBS casting pot while the lead got up to temp.

I immediately discovered the RG4 design wasnt compatable with my bottom pour RCBS pot as the mechanical parts on the bottom of the mold would just hang up on the mold guide bar. Then I tried to ladle pour into mold and while I got better results in neither case could I get a bullet to completely fill out. I tried for a good while until I got frustrated and decided I better set the thing down before I threw it down the driveway......

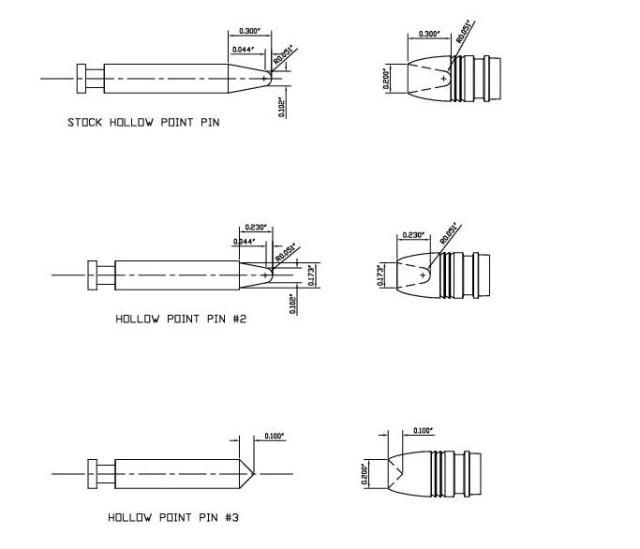

In my opinion, the HP pins are WAY TOO BIG!!! My alloy is 50% Linotype and 50 percent range lead and I have never seen a mold where I couldnt fill out the bullet! Even if the bullet was filled out just right, I doubt it would run thru my Star Sizer without collapsing the Hollow Point cavity.....

While Im very dissappointed, Im standing by to hear of your results......

|

|

|

Reply With Quote

Reply With Quote