I have to brag, and ask a question.

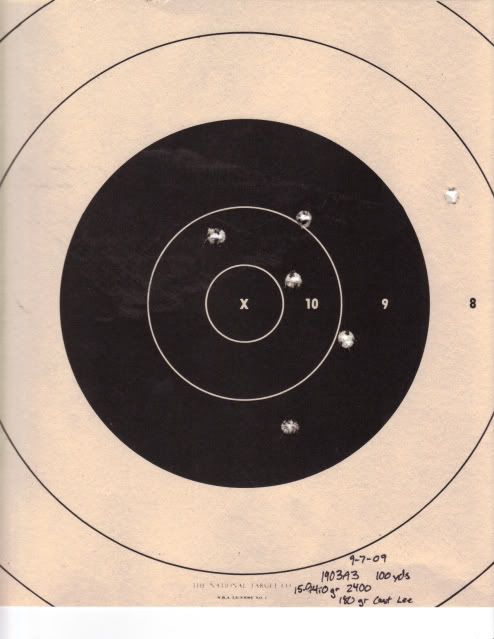

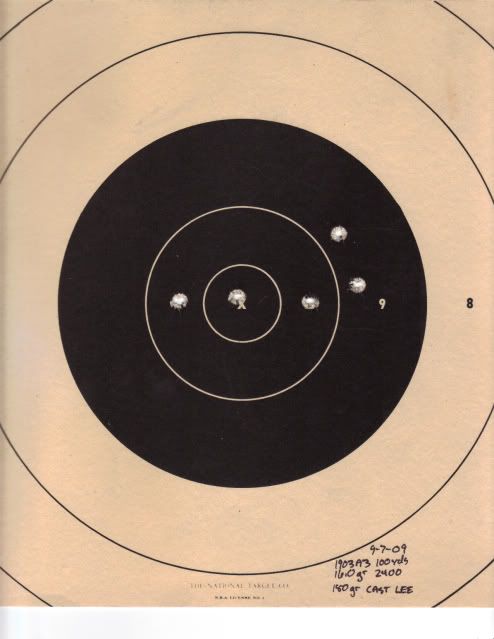

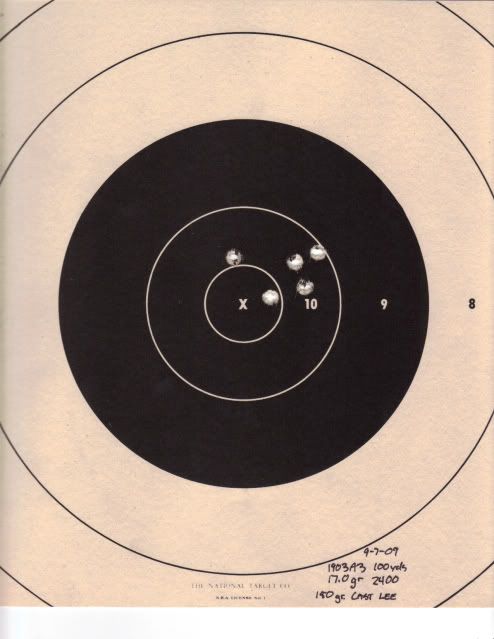

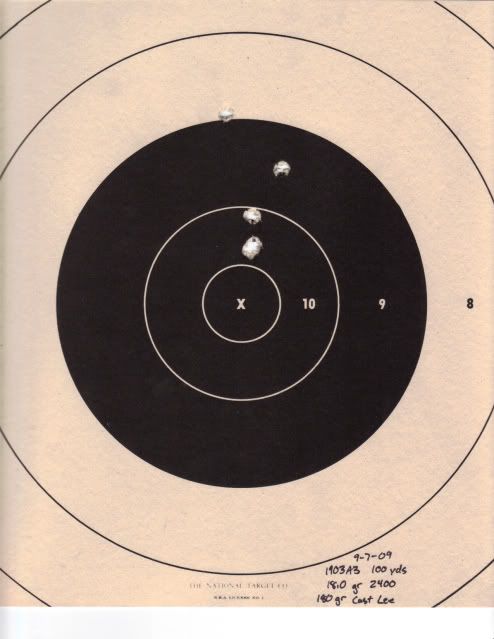

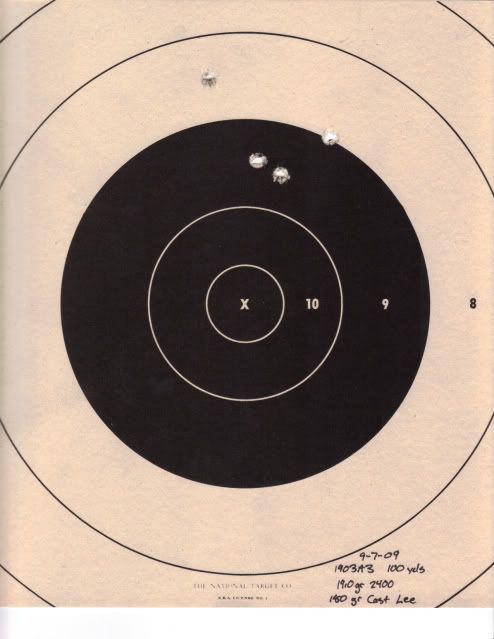

Below are the targets of my first cast bullet loads.

Info:

Rifle: 1903a3 Springfield with as issued iron sights

Range: 100 yards

Case: R-P and Winchester

Bullet: Lee 180 gr RN, tumble lubed, gas checked, sized to .309"

Primer: CCI LR

Powder: 2400, 15.0 gr, 16.0 gr, 17.0 gr, 18.0 gr, 19.0 gr

COL: 3.23

Crimp: light Lee Factory Crimp Die

It looks like the 17 gr. load is the winner. More testing will need to be done to confirm. 5 shots measured 1.3", 4 shots measured 1.1"

The only thing that concern me was the raised primers on most of the cases as shown in the picture. Is that a sign of excessive pressure in this case, or not enough, or is that normal with light cast loads?

Is this cast bullet thing really this easy?

By the way, I sized the COL on this rifle, but I also brought my 1917 Enfield along and they wouldn't chamber in that one. So if I need a universal .30-06 I need to do some more experimenting.

I am planning on using these for CMP matches, now I need to test them for 200 yards (that's what my local CMP match is shot at).

Thanks for looking.

|

|

|

Reply With Quote

Reply With Quote