Gentlemen;

I've just purchaced a K-31 Swiss in excellent condition - all matching numbers and the soldier's name it was issued to under the butt-plate.

I know a few things about the rifle and how to load for these military outfits but naturally I don't know it all!

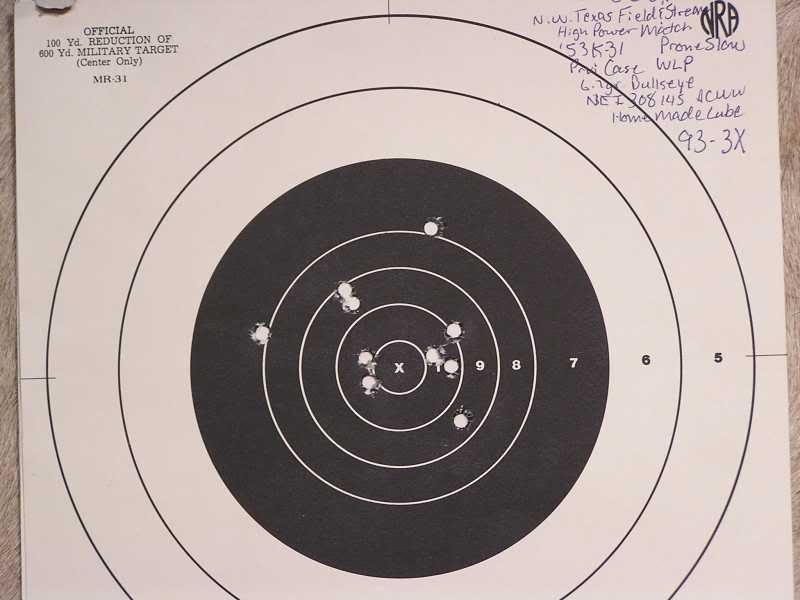

I'm requesting the membership's input about successful cast bullet loads and techniques for feeding this particular design. Please to include any special treatment of bullets and diameters such that they will enter the throat consistently and accurately.

Thanks in advance,

Forrest

|

|

|

Reply With Quote

Reply With Quote