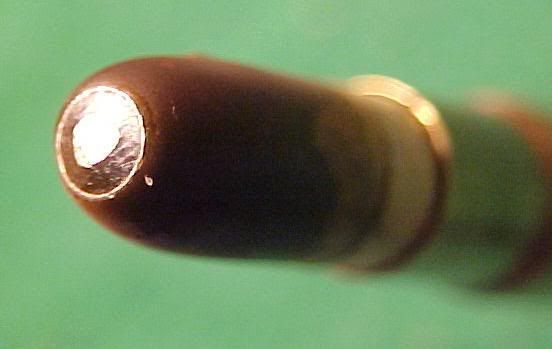

This is the patch;

I used a mix of any old bullet lube, candle wax and STP. This stuff lubes quite well and holds my hornet bullet seated in it's paper cup. I am trying the same stuff now. I have three newly loaded rounds and the bullets are quite firm i.e. I can't pull them out with my fingers.I will shoot them singly (checking the bore between shots in case the paper stays behind!)

I never had a paper cup stay behind in the hornet bore. (The lube also kept the bore clean and rust free and prevents any copper fouling - that with .224 bullets down a .223 bore).

|

|

|

Reply With Quote

Reply With Quote