Right - to hell with working (got halfway through and found I don't have any kero!). So.....

Like this?I know, the molds you are makeing recquire the gas check. If you get a chance, make a mold that does not. Perhaps a nose pour.

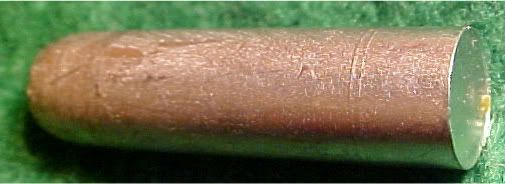

Here it is patched. I twisted the tail. This time I did not wet the paper - instead I dipped it straight into the molten 'waxy-lube'. (It's tissue paper which is a tad fragile when wet!) Next time I will leave the base part unwaxed.

I will go get one of those cigarette rollers - the two shops I looked in did not have them.

Oh heck! I better walk to the nearest shop and get some kero!

|

|

|

Reply With Quote

Reply With Quote

)

)