Hi everybody. Sorry, I got a little long winded here.

So there I was... Sitting in my deer stand watching all the button bucks walk by, wishing something shootable would show up... And I thought to myself, self I need a new gun for shooting Hogs. Well, not like I really "need" a new gun, but a guy Needs to have a project every now and then to keep the creative juices flowing and all. Right?

Anyway I had thought about the 358 Yeti, but it uses a cu$tom reamer, cu$tom dies, and an unobtainium cu$tom bolt and extension for the AR15 platform. So I thought about using a stock reamer and dies for the 358 Winchester and just running it in far enough for a max length case and still be able to use 180-200gn bullets. I'm not interested in shooting subsonic with super heavy bullets, so make the case as long as possible for max case capacity and still fit in an AR 15 magazine.

So I pull out my phone and start ordering supplies. Midway had Hornady 200gn FTX and Interlock, but the Speer 180 FN was no where to be found. I also ordered some Lee 358 Win dies, plus an extra 358 Win sizer die. A few days later Midway got in some Speer 358-180FN, but they had a limit of 2 every 14 days, so I clicked buy it now before they all disappeared. About an hour later I thought I'd try to place a second order, but they were sold out.

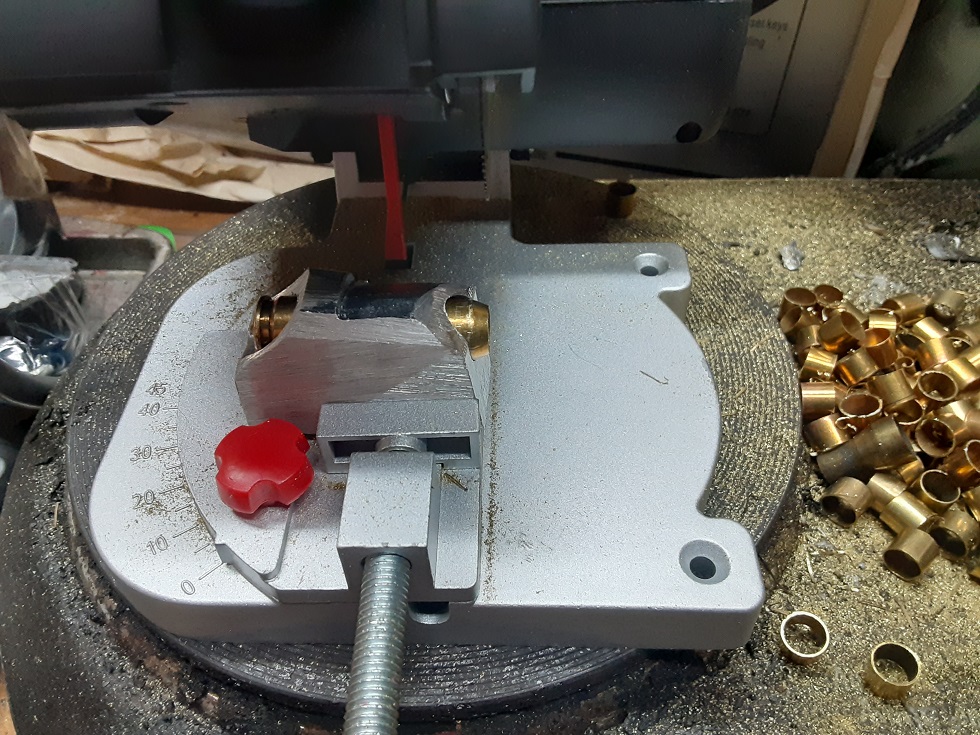

So a couple weeks later I get home from Deer camp and start mocking up cases. I chopped off a 308 case lubed with Imperial wax and stuffed it up into a 358 sizing die with the expander/decapping stem removed. I used the shell holder extension from a Lee bullet sizing set to run the whole case up into the die. Then I used a 5/16" punch and a small hammer to tap the case back out. I measured the noses of the bullets and the inside of an AR15 magazine. The metal 450 Bushmaster mags measure 2.300" inside, so I set my COAL to 2.290", did some math and came up with a max case length of 1.660". I ran the case through the trimmer, deburred and tried to seat a bullet. I could only screw the seater stem down so far so the bullets were about half seated. I pulled out the grinder with a cutoff wheel and chopped about 3/8" off the bottom of the sizer and seater dies, then cleaned them up on the buffer wheel. Now I could seat the bullets.

The cast bullets are the Lee 200 and my Fat35(265gn)

I stuffed them into some magazines and it looks like they will work.

A quick measurement with the calipers showed the necks were way too fat. So I ordered a 35 cal pilot for the Hornady neck turner. A couple days later Midway delivers again. I turned the necks for a thickness of .015" and they looked great.

I contacted a few AR barrel makers and found Deadshot Barrels in Oregon that said they would make me a barrel if I could supply them with a case and bolt to headspace on. Back to Midway for a 450 Bushmaster bolt...

I shipped them a couple of cases and the bolt on Dec 20th, they said 5-10 weeks lead time, so now I'm waiting...

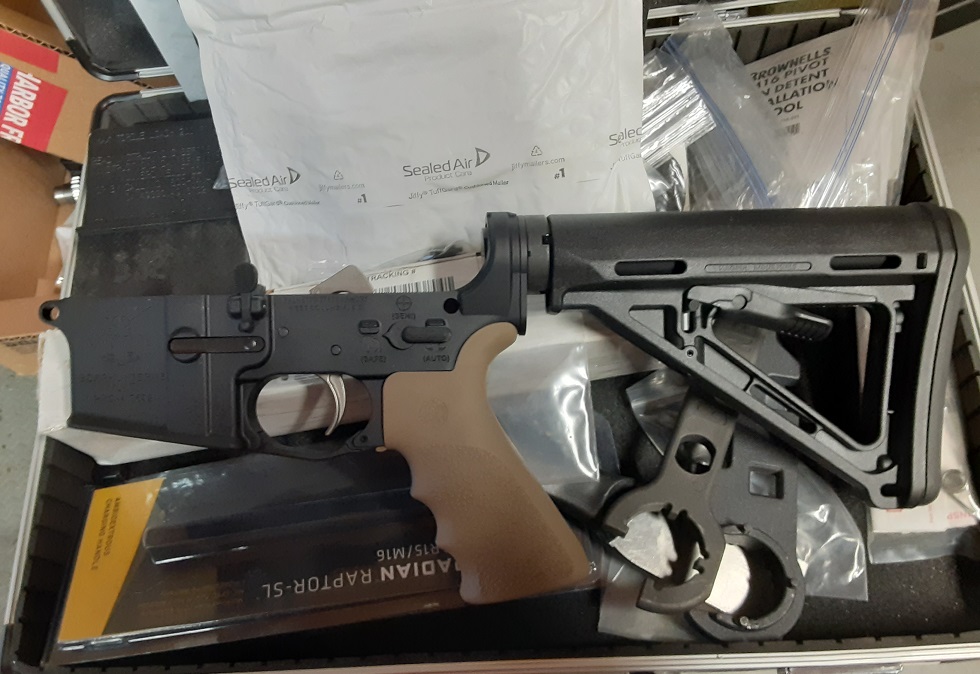

While I was waiting I searched PSA and saw they had a special run of Boar Hunter 15 lowers in stock, so I had to have one of those...

Now the lower is all put together.

With a little help from you guys, it looks like Winchester and Hornady have the most case capacity in 308 Winchester. So I ordered some of those to compare with LC and RP brass.

My formed cases hold 45.8gns of H20. So now it time to setup a new cartridge in Quickload...

It looks like RL-7 is going to be the powder with a max pressure of 47kpsi. (I looked at bolt thrust numbers from several existing cartridges, It looks like most are running around 8000 lbs, so divide by the area of a .470" case head and you get a little over 46kpsi. I ordered the 9310 bolt which is supposed to be 7% stronger, which comes out to a little over 49k, so I'll try 47k and see what happens.)

I should be able to get 2340fps with the 180 Speer and 2150 with the 200gn Hornady's, from an 18.5" barrel.

If I can compress RL-10X, I might be able to do 2400 and 2180.

Look what Mrs. Claus wrapped up for me this year.

a Sightmark digital IR Scope for shooting Hogs at night!

2 weeks have passed so I was able to order another 2 boxes of Speer 180s.

So what haven't I thought about?

|

|

|

Reply With Quote

Reply With Quote