I've been toying around with a redesign of a boolit for the 7.62x25 that I had done back around 2010. The original boolit, which I used Mountain Molds for, can be seen here: https://bulletmatch.com/bullets/moun...ulds-311-90-rf

At the time I designed this we were still faced with the problems of traditionally lubed boolits in the 30 Tok: It has a short case neck without much room for lube or a gascheck. Because of this many existing designs would work, but were not optimal in my opinion. Because of this I worked up the design you see there. Several other similar designs came about during this time frame. One I know was designed by Al, and is almost an identical clone except for some differences in nose profile and weight, being a little lighter at 85gr if I remember correctly.

The problem I saw with these designs was the amount of lube they could carry as well as not having a gas check in most cases. However, now we have Powder Coating... And as such really shouldn't be limited by the Tok's short case neck.

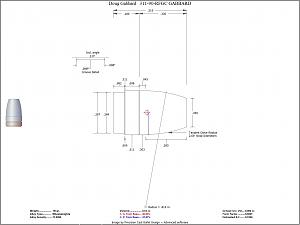

The boolit I had previously designed shoots well both traditionally lubed as well as PC'd. However, without a gascheck I feel it is somewhat limited where velocity was concerned. Remove the lube groove, add a gascheck, change the meplat from .184 to .200 (65% instead of the original 60%), and adjust the ogive to give a slightly better BC for use in my 7.62x25 rifle project. Ultimately what I came up with is what you see below. It should come in at 90gr as cast, and right around 95gr once PC'd and fitted with a gascheck. I've toyed with a HP design as well, which looks like it should cast around 85gr, and 90gr with PC and gascheck, but is just an idea at the moment...

I'm looking for any comments, critiques, concerns, etc.

|

|

|

Reply With Quote

Reply With Quote