Have you tried cutting a relief into the expander diameter.

That will greatly reduce the case length that contacts the expander, and minimize the sticking.

Here's a pic:

You could chuck the expander in a drill, clamp the drill in a vise, and carefully cut that relief with a cut-off wheel in a Dremel type tool.

A drill press would work better if you have one. (a lathe would be even better)

Ideally, you would leave only about 1/8" length of the original diameter at the very end, like the pic.

The other end of the relief would be at the step, lengthening and blending that transition.

There's no "M" step in that expander pic. just a flare angle.

.

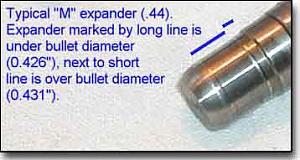

Edit: here's another pic of an "M" expander showing the undercut/relief:

Ignore the verbiage.

.

Reply With Quote

Reply With Quote