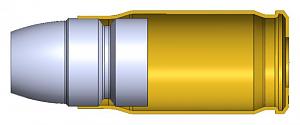

I’m looking to get a two cavity mold from Accurate, one cavity for each boolit shown below. These are for .357SIG and I’m wondering what kind of feedback I can get from you folks. One design is intended to be PC, and has two shallow grooves to reduce pressure via reduced bearing surface, and one of these grooves is a semi-cannelure intended to help with setback (I have successfully used cannelures on .357SIG). The other boolit design is for traditional lube, and I am placing & sizing the lube groove to minimize loss of neck tension without exposing powder to the lube. I’m not sure how much volume of lube I should have, so maybe I can make the lube groove a bit more narrow to increase neck tension. I want a large meplat with sharp corners, but I had one issue with a 0.280” meplat getting snagged on my feed ramp so I’m at a 0.250” meplat.

*

*

|

|

|

Reply With Quote

Reply With Quote