I don't have the Spence Wolf book but I borrowed and read it. There is some info I don't agree with and I also tried some of what he mentioned and it added brass to the brass scrap barrel.

If you're getting a bunch of vertical it's more likely from not enough fouling control or just important is the case prep and loading the components, also controlling the rifle and position behind it.

When I get a new lot of powder I do the ladder load test using the same wads/powder/primers/bullets/alloy and just change the compression.

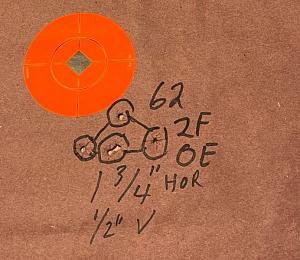

Target 1-3 you can see the difference what just changing the compression does by a one grain increase of powder. Those three targets were shot at the 200 yard line with no sight changing allowing for the conditions.

The white target was shot using a new mould I got from Rick at KAL and worked up the first load developments at close range before moving out to the 200 yard line. You can see the difference just with different powders. Those three targets were the final ladder load test.

Use proper fouling control, case prep and load development.

Enlarging flash holes and mag primers never did the job for me shooting black powder.

Uniform your brass so you have consistent case neck tension for a good bullet release so you dont get a bunch of odd chamber pressures will help a lot also.

Breach seating the bullet is a large help that eliminates bullet release from a fixed shell holding a close chamber pressure.

Reply With Quote

Reply With Quote