The over-travel ring is not strictly necessary but, if you are using either of the Lee, case-activated, powder measures, it will prevent over travel adjustmet from harming the Lee Auto-Drum(which Lee cautions against) and possible incomplete powder drop from the Lee Auto-Disk measure.

With the Over-Travel ring in place, adjusting the measure down too far will only cause excessive flare to the case neck, possibly ruining the case. Without the Over-Travel Ring in place, excessive downward adjustment will force the drop tube too far into the measure which, Lee states, can cause damage.

Better to ruin a case with over-travel adjustment than an expensive powder measure.

Due to the interior space in the Lee Powder-Thru-Expander dies and the geometry necessary to provide adjustment for a wide range of case lengths. the length of the spacers and of the expander dictated the use of a 2mm thick ring to allow precise adjustment for 153 of the SAAMI caliber case length specifications from 0.605 inches to 2.700 inches.

Even if one were to not use a case activated measure and either dip through a funnel or mount a hand operated measure to the die, without the ring, some case lengths would not have enough adjustment to completely expand and step the case neck.

Hope this helps.

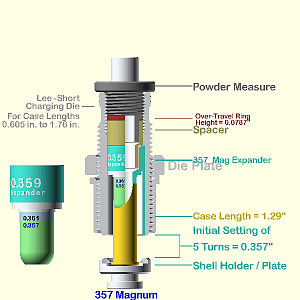

I am encloseing an updated Openscad image of the setup combination for your 357 Magnum operation. The cutaway images illustrate the necessary use of the Over-Travle ring.

|

|

|

Reply With Quote

Reply With Quote