Poppy, yes I set the timer on the oven to 20 minutes. I shake the bullets with black airsoft BB's in a Walmart mug with lid:

The powder coating I use I believe is Prismatic Powder. I think that is what the guy called it. I visited a powder coating shop near my house and asked to buy a pound of their powder. The owner of the shop asked what for and I said "powder coating bullets for shooting". He was also a shooter so he gave me about 2 pounds for free. This stuff works very well and the coating easily holds up to handing with Harbor Freight nitrile gloves. In fact after stacking the bullets in the plastic trays, I slam the tray onto the baking tray a couple of times to even out the powder and remove excess.

The clinging action of the powder to the lead is simple static electricity which is generated by making and breaking contact between 2 materials on the triboelectric series. That means the harder and more vigorously you shake, the better the cling. Little dot sized bare spots on the bullet will be covered as the powder melts in the oven. I've timed myself and I have trouble (patience wise) with shaking for much more than a minute so I make sure I shake for 1 minute. I've tested a Harbor Freight vibratory tumbler with the bullets in a gallon sized Ziplock bag for anywhere between 2-5 minutes and about 3 minutes was optimal, but every time, the powder came out looking darker than it went in. I believe this is probably powderized lead so I stopped this method. Shake and bake by manual shaking is best. In the dry Sacramento air, I've gotten away with nothing more that bullets and powder in a 1 gallon Ziplock bag and gently massaging the bag for a couple of minutes and that worked out fine. I've seen some folks use a big section of PVC pipe with screw on ends and that worked out fine but it's a balance between how many you do and how much work you have to put into the shaking effort. The cup method works well for me and I no longer bust up Cool Whip tubs or low cost "Tupperware" containers.

With the bullets arranged on the tray, I can get 200 done in a bake. So it takes 5 bakes to coat 1000 bullets. While one tray is baking, I am shaking and stacking for the other oven and can get that done in about 10 minutes. So by leap frogging the ovens and starting/finishing a bake every 10 minutes, the 5th batch is done at the end of an hour.

The cost is minimal. Even with $10-$15/pound powder, you're only using about 1/2-1 teaspoon of powder for 100-150 bullets. The ovens were $20 each at Walmart. I was using $5 ovens I bought at Goodwill in California but I threw them out in my move to Texas thinking I could replace them for another $10. Goodwill stores out here are far worse stocked than the ones I was used to in the Sacramento area. I'm glad I brought all my baking trays because it's a good idea to have at least a half dozen baking trays so you can stack on a couple, bake on a couple and allow a couple to cool down after the bake.

The California central valley was ideal for PC'ing because the summers were bone dry. I was afraid that the Texas humidity would hurt my powder coating efforts but in fact, it's not bad at all. I now do my powder coating in the garage of my house and have managed to perform the work without making a mess. I think the trick is to keep your powder in compartmented containers so you don't contaminate the whole batch with humidity each time you open it and to do the opening indoors away from the outdoor humidity if you're in that climate. A few years back I wanted to see how "badly" I could powder coat and what the effects were. I PC'ed a batch of bullets on a humid California morning and got a "good" splotchy coating on the bullets.

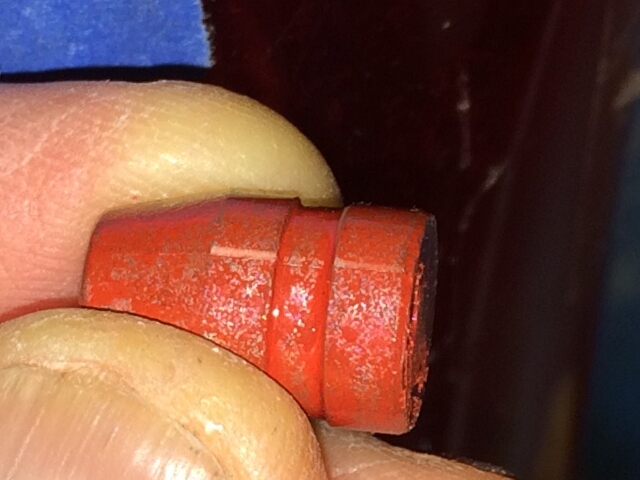

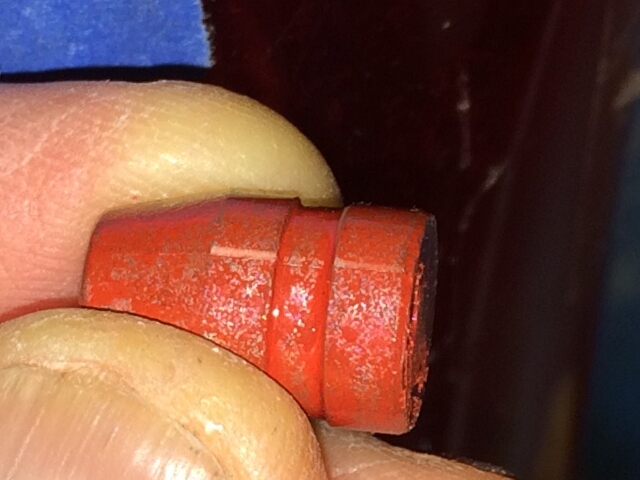

I then sized the bullets and you can see that even though the pigment was splotchy, the polymer flowed evenly over the driving bands.

Shooting 200 rounds in one session showed no fouling and no leading in my M&P40. So even a blotchy powder coat job is perfectly satisfactory for shooting, they just don't look too nice. But at 1050 fps and 25 yards, you won't notice the difference.

So to powder coat bullets, you don't need to spend much money or time. Optimistically, I would say it would take me 2 hours to cast, 1 hour to coat and one hour to size. Add an hour for set up and clean up for casting and 20 minutes for set up and putting away my PC setup.

Hope that helps

Reply With Quote

Reply With Quote