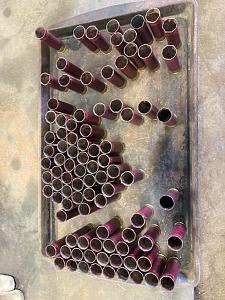

I ran some paper Federal hulls through my crimp straightening process yesterday. It consists of putting a homemade flare tool in my drill press, then heating that with my hot air gun, set to 650F. Spin up the flare tool and push on the hull - hold for a count of 3 and you have an "ironed" hull that can be reloaded pretty easily. See pics for graphics of before and after.

|

|

|

Reply With Quote

Reply With Quote