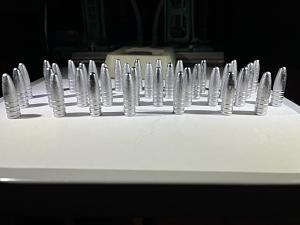

This is my first attempt at casting bullets. I don't have an experienced caster to hold my hand so I'm basically fly by the seat of my pants here. What little I do know I've learned by reading this forum. I used my plumbers pot and propane stove and was constantly adjusting the temp. I did preheat the mold and at one time even had it to hot and the sprue took a while to set.I will use my Chromalox 50 from here on out because it holds a steady 730 degrees. I noticed some bullets came out shiny and most have a frosted look to them. What is the cause of this? Attached is a pic and any input is welcome. I need constructive criticism its the only way I've ever got better at anything. Thanks, Rob

|

|

|

Reply With Quote

Reply With Quote