When I measured the headspace on my Winchester 94 fired 30-30 brass I was quite shocked how long it was and how much it varied compared to factory ammo. Factory Winchester ammo measured average 1.472" while the 1x fired brass in my gun measured 1.509" average and it varied from 1.501" to 1.513". It also seems like the low charges of Unique (10-11gr) with light lead bullets produced longer stretched headspace where as the 2nd time fired brass using 150FMJ and middle of the road full power charges the headspace was at 1.505". I've never seen anything that varied so much in the typical cartridges that headspace off the shoulder so I am curious if this is typical in lever guns and what kind of headspace are you getting?

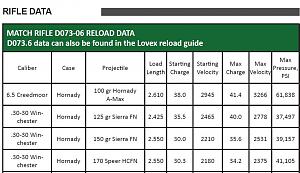

2nd question is I am using Shooter's World Match Rifle powder and their load data shows 2531fps at max charge of 35.6gr, I started with with 32gr and went up in 1/2 grain increments to 34, the primer looks fine, brass case head looks fine. How do I know when it's bad and I need to back off? I am using this powder because I have plenty of it. Other powders I have that I saw in Hornady manual is Ramshot TAC, an opened can of ancient 748 and generic BL(2).

|

|

|

Reply With Quote

Reply With Quote