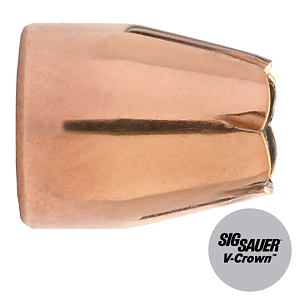

So I realize this isn't cast bullets per say but you guys have more knowledge than most of the internet I would say. My issue is I want to use these 9mm bullets which are FMJ without a cannelure. I don't know how I should go about crimping them. They will be used in a KP9 which is a AK style rifle and I want to avoid setback in the casing. Can I use my LEE factory crimp die even when there is no cannelure?

|

|

|

Reply With Quote

Reply With Quote