Larry,

You make some good posts with your cast bullet information.

I'm very annal with my cast bullets because I shoot most matches at long range and for this purpose you need to spend time getting the proper alloy and put that alloy in a mould casting a good bullet.

I have spent a lot of research time with alloys that will hold the bullet from getting setback that will result in bad accuracy if the operation gets moved out of balance.

Most of my shooting is with bullets 500 grains plus and the the way I cast I seldom get a bullet under one grain light from the heaviest when ever I weigh them, seldom do I do that

What I found causes some of the light/heavy variances is dross getting into the cavity from the ladle spigot. I have split light bullets to see the voids and all I have ever found is dross.

Also I found that improper mixing the alloy. Tin is light or if one uses ww a the lead mix the WW are lighter than the lead and if you don't get the mix blended you could pick up the lighter or heavier mix and the results will be weight variance. I mixed alloy in the 20# Wagge lead pot with just dropping the lead tin ingots and storing it with a spoon a few times with flux and I found perfectly cast bullets weighing as much different as 1. 7 grains.

The next batch was mixed with the same amount of lead/tin by weight but I used a paint mixer you put on a drill motor and I mixed and fluxed that pot using it for a longer time frame and cast a bunch of bullets and only 3 out of 50 went a 1/2 grain light from the heaviest. I don't know if a proper mix does this or not but I spend the extra time doing it.

A sprue plate to loose will cause heavy or light even when properly filled mould.

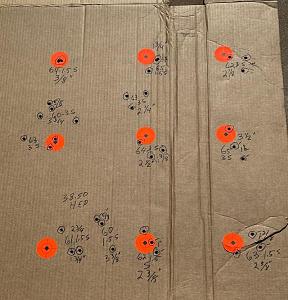

When you get bullets like this after they leave the muzzle looking like this.

The results should look like this if you do your part behind the buttplate and find the proper powder load.

The first two targets were ladder loads at 100 yards and the small target was a follow up test at 200 yards.

A cast bullet will shoot well if all components come together properly.

Just don't push them to hard

Attachment 299904[attach=config]299896[/attachAttachment 299895[attach=config]299897[/attach

|

|

|

Reply With Quote

Reply With Quote