Well, the wonderful brown truck delivered my new toy yesterday.

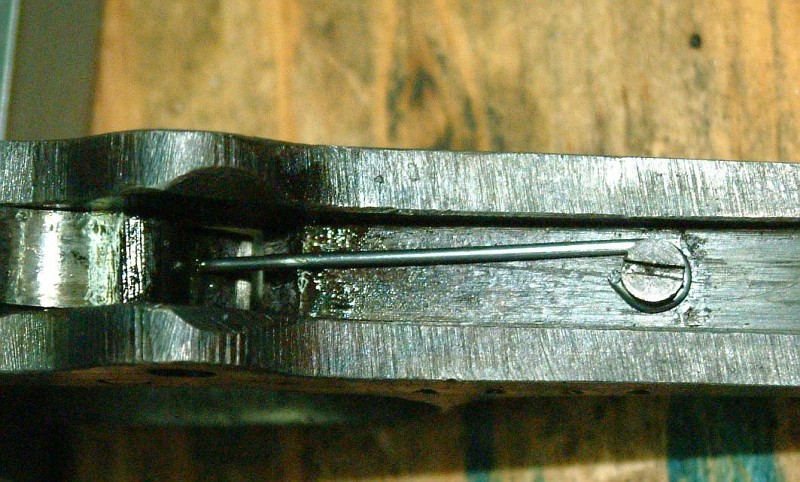

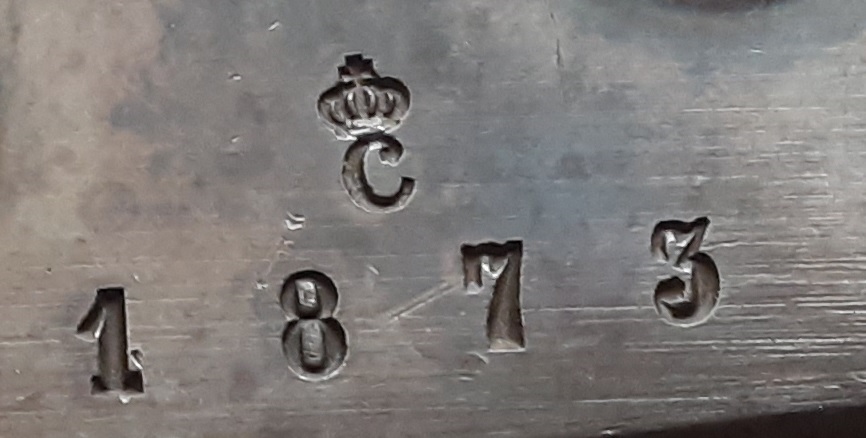

It's a Carl Gustaf Rolling Block in 12.7x44R.

I'm wondering what kind of wood they used in these rifles?

The pattern on the wood reminds me of a Muzzle loader scratch build show I watched awhile back where they used iron filings and linseed oil to coat the stock, then put a hot iron next to the wood to burn a pattern into it.

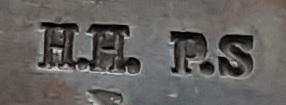

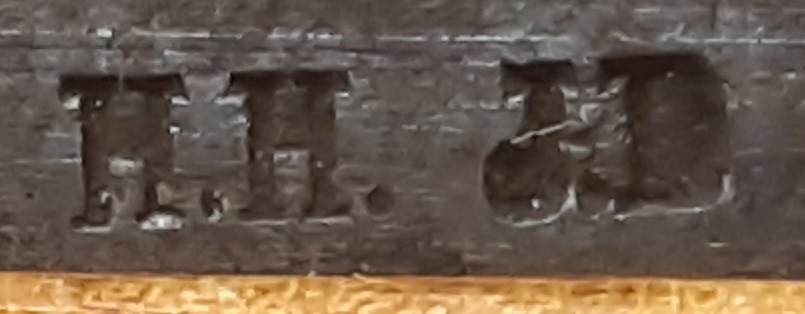

Anybody know what the proof marks are on it?

I'll try to get some good pics of the entire rifle tomorrow.

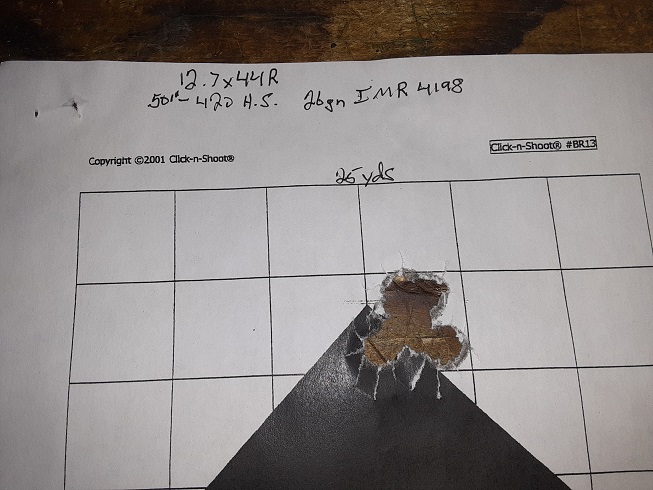

Hopefully get to test fire it tomorrow also if it doesn't rain the whole day.

|

|

|

Reply With Quote

Reply With Quote