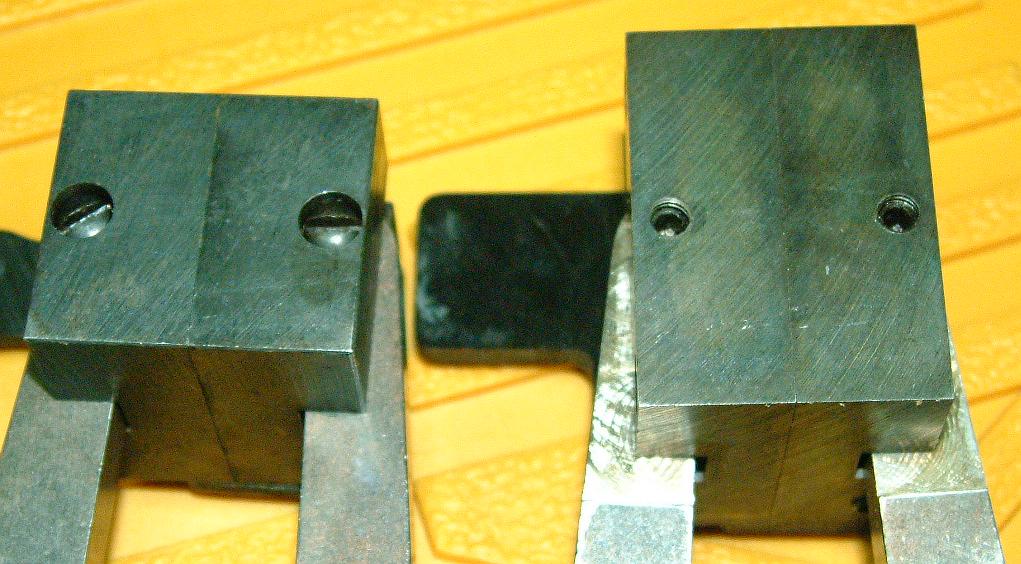

I hear Lee handles will fit Lyman molds.. How do you remove the Lee handles? Mine appear to have tiny Allen screws. I couldn't get them to turn out. Then I read where they are pins. But a Allen wrench will not go into a pin..any one know about how to remove them..I need handled for my new Lyman hollow point mold..thanks

|

|

|

keep on rolling along.no matter what happens just keep rolling

keep on rolling along.no matter what happens just keep rolling

Reply With Quote

Reply With Quote