Something shaped like the Accurate 35-125B or 35-130A might solve your problem, but if you've already reamed the throat, I don't see how.

I'm also puzzled as to how your leade can be smaller than your GROOVE diameter, unless you're discussing the beginning of the lands. The BORE of every 9mm I've pin gauged so far has been .346"-.347" (including polygonal and "Marksman" Glocks and a Hungarian BHP clone). A pound casting of your chamber might be in order.

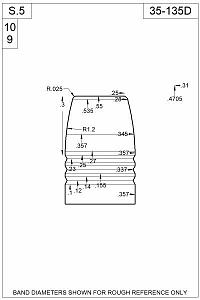

My advice would be to FATTEN up your nose to work within the space you have. I'm running the NOE TL357-135-RF "Ranch Dog" which is very nearly the same bullet as Accurate's 35-135D. I call your attention to the blueprint on the Accurate:

Note the taper from the end of the .357" diameter shank to the .345" diameter at .357" forward of the base. If your brass is taper-crimped to the regulation .380" O.D. at the mouth, and you're seated to where the beginning of that taper starts at the case mouth, it would be a very tight chamber and throat indeed to stick on that profile.

For accuracy. . .you might measure your case wall thickness, then pin-gauge the interior of a fired case and the front end of your chamber to see if you have enough room to get correct cartridge dimensions while seating a .358" diameter bullet. My bore sluggings on the same guns as above have given me groove diameters of .355"-.356" and .357" bullets seem to work, but fatter may help you out.

ALSO: is it possible your brass is sizing down your bullets on seating? The obvious indicator of that would be lead fouling, but if added speed is causing your accuracy woes, I think this may be the problem. Might be worth pulling and measuring one of your bullets to find out. Your factory dies are probably spec'd for a .355" diameter jacketed pill, which is not what we're playing with. I ended up using a Lee .38 S&W sizing die to get a little more expansion to prevent this.

Hope that gets you up and running.

Reply With Quote

Reply With Quote

DougGuy

DougGuy