I sent my Blackhawk to Ruger under a warranty claim, requesting a new cylinder with smaller diameter cylinder throats. They told me that .454 is within tolerance and sent the gun back to me without a new cylinder.

|

|

|

I sent my Blackhawk to Ruger under a warranty claim, requesting a new cylinder with smaller diameter cylinder throats. They told me that .454 is within tolerance and sent the gun back to me without a new cylinder.

Last edited by JCM45; 07-12-2021 at 04:51 PM.

I had to send mine back for a transfer bar replacement. On a whim, I sent the cylinders and complained about the oversized throats - greater than .456" on the colt cylinder.

It came back with two new cylinders and a new transfer bar.

Last edited by cabezaverde; 07-12-2021 at 05:04 PM.

Founder of the Single Shot section.

A government big enough to give you everything you want is big enough to take everything you have.

8 in the 10 ring, then I get a PING. Love my Garand.

Cast some bullets with Linotype & size to your groove diameter + .001" at the most. Puts a stop to skidding & slump. Test .

I opened a RCBS 45 acp seating die with a wood dowel & emery paper. But you have a LOT OF METAL to remove.

Making a die may be easier?

This makes me wonder if that was the problem with my friends late 70's BH .45 Colt. Side by side shooting with my BH .41 mag was embarrassing for him. My Star PD.45acp would also out shoot it with any load I came up with. He sold it and when he got into CAS years later, he bought Uberti 1873 SAA- a pair- and a .45 Colt Uberti 73 Winchester clone. Those three were great shooters.

Sent from my SM-A716U using Tapatalk

And shoot these through throats .005" bigger? Laughable advice.

Many years ago, the same BH I referenced in this thread in an earlier reply, with .456" throats, I fed it EXACTLY what you are recommending. I used near pure lino boolits, sized maybe .451" which was the same as groove diameter. I DESTROYED a Lewis Lead Remover with a ball peen hammer trying to de lead the barrel. It was HORRENDOUS. Unbelievable leading.

I would not suggest the OP do the same thing.

Last edited by DougGuy; 07-13-2021 at 02:27 AM.

Got a .22 .30 .32 .357 .38 .40 .41 .44 .45 .480 or .500 S&W cylinder that needs throats honed? 9mm, 10mm/40S&W, 45 ACP pistol barrel that won't "plunk" your handloads? 480 Ruger or 475 Linebaugh cylinder that needs the "step" reamed to 6° 30min chamfer? Click here to send me a PM You can also find me on Facebook Click Here.

I am getting really tired of reading the same old Lyman disinformation about using hard bullets sized to the groove diameter of the barrel. Keith had it right in his Sixgunner452 Cartridges and Loads, 1935.

The ENEMY is listening.

HE wants to know what YOU know.

Keep it to yourself.

Thinking aloud here. I think this is my plan.

For my own interest I am going to record a few targets shot with the ammo made with the RCBS 250 grain SWC - Diameter 0.452". That mold is long gone but I still have some bullets from it.

8grs of Unique has been my long standing load in the 45 Colt with 250 grn bullets.

I am goin to make a seater die to seat the 0.457" LBT 255 grn bullets without shaving them and record how that groups. 8grns Unique

At that point I may contact Ruger to see if they are interested in addressing this BH. DougGuy's well thought out aproch outlined in the above post sounds like the voice of experence. I can use that as a guide. If Ruger takes it back and refits it with new cylinders, I can compair it with the earlier targets shot with the large cylinders.

I find it interesting as a project.

Chill Wills

Hard bullets deform less when they hit the forcing cone. Lyman has said sizing down more then .003" will hurt accuracy.

Sizing by die or forcing cone, SAME.

Do your own testing as always.

Last edited by 243winxb; 07-13-2021 at 05:04 PM.

Last edited by DougGuy; 07-13-2021 at 06:06 PM.

Got a .22 .30 .32 .357 .38 .40 .41 .44 .45 .480 or .500 S&W cylinder that needs throats honed? 9mm, 10mm/40S&W, 45 ACP pistol barrel that won't "plunk" your handloads? 480 Ruger or 475 Linebaugh cylinder that needs the "step" reamed to 6° 30min chamfer? Click here to send me a PM You can also find me on Facebook Click Here.

Sizing more than 1% of bullet diameter with the Lyman bullet base and nose deformer and in the case of heavy bullets, also a body bender, does hurt accuracy, but due to inherent design defects of the antique machine. If bullets must be sized they should be pushed through the die nose first. But best is to have bullets drop to correct diameter so that no sizing is needed.

The ENEMY is listening.

HE wants to know what YOU know.

Keep it to yourself.

Shooting as-cast boolits can be good or it can be hit or miss because you often have parting lines which makes the boolit larger on one tangent than the other tangent so it is in effect an oval of sorts, which could work either way, you could get some interference if the oval part is larger than the throat, or you could get some gas bypassing the boolit if it is significantly smaller than the throat but with a soft alloy and soft lube, if you load over a decent enough powder charge, you could get obturation to bump the boolit to throat diameter in which case you could not ask for a better fit in the throats.

Even when I have boolits that I know are sized and lubed correctly, I STILL run them through a push through die just to weed out any inconsistencies before loading.

Got a .22 .30 .32 .357 .38 .40 .41 .44 .45 .480 or .500 S&W cylinder that needs throats honed? 9mm, 10mm/40S&W, 45 ACP pistol barrel that won't "plunk" your handloads? 480 Ruger or 475 Linebaugh cylinder that needs the "step" reamed to 6° 30min chamfer? Click here to send me a PM You can also find me on Facebook Click Here.

I machined a new seating die to except the larger diameter bullet. Basically I used the RCBS die as a pattern and improved the new one to meet the needs of the oversized ammunition. I took the time to load 12 rounds and it works well, seating the 0.457" bullets into the cases without pinching the case before the bullet could be seated. The old die was closing the expanded mouth back down before the 0.457" diameter bullet had a chance to get into the case. And that was sheering a ring of lead off the side of the unseated bullet.

In the picture of the empty case and loaded round, you can see the scuffed brass as the case and bullet combined diameter was too large for the RCBS die to swallow. This resulted in lead shaved during seating as well as pinching the case - reducing the bullet in the die.

Chill Wills

Ammo loaded in the new seating die. No shaved rings. No pinched brass. The five loaded rounds are three Starline in the middle and two R-P cases on the ends. The R-P cases work well. The Starline must have slightly thicker case walls. The R-P cases are a joy to load and the crimp comes out better. As the cases show, the crimp on the Starline cases still needs some work.

Chill Wills

I seldom disagree with outpost75 but I do here. My testing years back with the 44 magnum [Hawes SAA & S&W M29] the 45 AR/ACP [S&W and Colt M1917s and a S&W M25] and the 45 colt [Colt SAA and Colt New Service] in revolvers using a Ransom Rest with the target at 50 yards gave solid evidence on target that cast bullets that were .003" or more over groove diameter did indeed give less less accuracy than even the same bullet sized just .001 over groove diameter.

For years before Venturino (?) wrote the article on oversize bullet being "more accurate" I had shot .356 sized 9mm cast bullets in 9mms, .358 cast bullets in the 38 SPL and 357, .429 sized cast bullets in the 44 SPL and 44 magnum and .452 sized cast bullets in the 45 ACP and 45AR. Accuracy was excellent with me be able, back then, to regularly shoot 1 - 1/2" 5 shot groups at 25 yards from a sand bag rest.

When I started shooting PPC I had a wonderfully accurate PPC revolver made by Power Custom on a M10 S&W action. I, like most all PPC shooters quickly found it was almost improbable if not impossible to duplicate the accuracy of Remington and Federal 38 SPL WC match ammo at 50 yards with my own WC cast bullet loads. That was the WCs fitting the throats of the cylinder at .457". I used an inertia bullet puller to see how "perfect" the factory WCs must be. They looked like regular Swaged WC we could buy. The weight variation was on par with my cast WCs but .....they were .355 - .356 diameter! I though the mild crimp may have swage them down so I cut the case behind the crimp and inertia puled 5 more.....they were the same diameter .... .355-.356! They were .001 -.002 under the throat diameter yet they gave no leading and were exceptionally accurate with no leading [most top PPC shooters used factory match WCs only at the 50 yard line].

So I ignored my own testing experience and went with the gun writers insistence that over sized bullets that "fit the throat" always gave improved accuracy and began using them myself. I quickly found if the bullets were .003"+ over groove diameter of the barrel to fit the cylinder throats accuracy would not be as good as with bullets just .001 - .002 over groove.

Why we ask? Well if we actually measured the diameter of fired undamaged lubed cast bullets we would find they can be .001 - .005 under groove diameter even if they started out .003 over groove diameter. Why is that? Because the bullet rides over a layer of lube is why. That lube thickness swaged the bullet down also. Thus if we start out with a bullet that is .003 over groove it can get swaged down .4 - .006+ under groove diameter. If we swaged/sized the bullet down .--1+ to make it throat diameter before loading it's even more.....That much swaging down does not do the concentricity of the bullet any good and, additionally, the base is "finned" pretty bad. All of which does not contribute to accuracy [precision].

As to the cause of "leading" in revolver cylinder throats and bores the use of an improper lube is most often the culprit.

Sorry it disagrees with you guys but that is what I have found. Thus I have gone back to .356 bullets in my 9mm's, .357 bullets in my 38 SPL and 357s, .430 bullets in my 44 Magnums and .452 bullets in my 45 ACP, AR and 45 Colts

The 3 most accurate revolvers I have right now [ Ruger 41 Magnum, Ruger 44-40 OM Vaquero and Colt Anaconda 44 magnum] all have throats the same diameter as the groove diameter [.410 in the 41 magnum and .429 in the Vaquero and Colt 44 s] so the bullets are sized .410 and .429. No leading and superb accuracy...way better than I can hold anymore.

Larry Gibson

“Deficient observation is merely a form of ignorance and responsible for the many morbid notions and foolish ideas prevailing.”

― Nikola Tesla

By the posts here and information elsewhere it appears 45's with large throats mostly come from one manufacturing era. Ruger must have been aware of the problem and then corrected it. Maybe over compensated. It is hard to imagine being this far off when they are capable of getting hundreds of thousands of things right in the course of making all their products. Not having ever worked in that type of business I am sure I don't know the half of it.

243winxb - the alloy most often used for all my handguns was WW with 1-2% tin added. Sometimes it would be 20-1 Pb-Sn. Both with about the same result. Only rarely did I experiment with lino in the hot 44 mag. In my whole life I have shot very little "full out: 44 mag loads.

A few people say they like pictures of the machining.

There are guys here that have a lifetime of professional experience cutting steel. I am sure they roll their eyes at us hobby types and how we do things, but still, it is good to be able to do some of this. Not a week goes by that I don't use my lathe and mill to address some problem around here - not just firearms.

Chill Wills

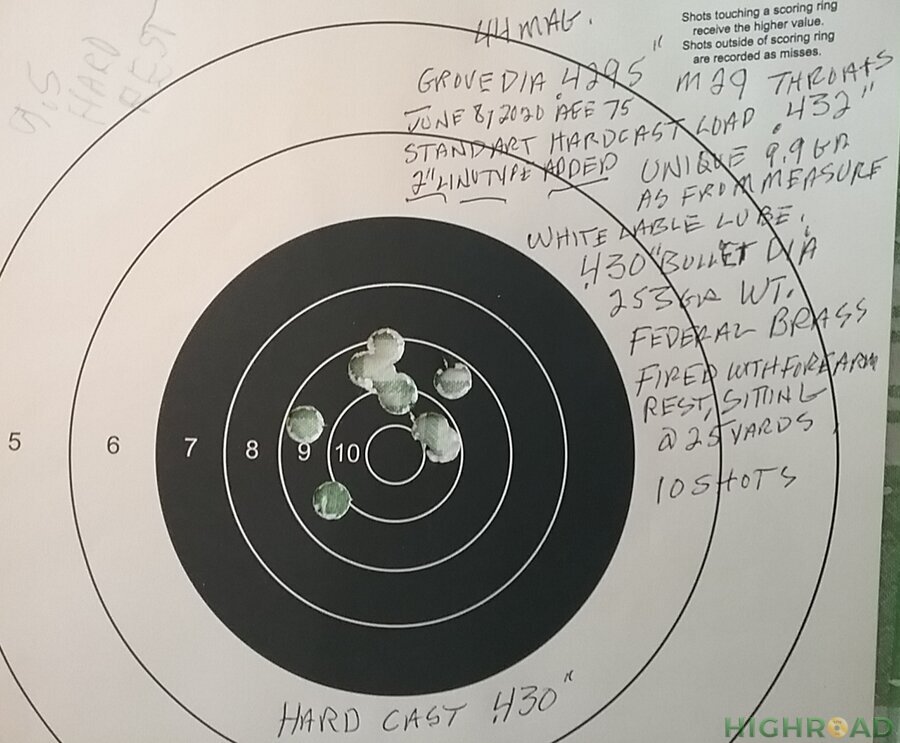

I had time enough today to shoot the four 5-shot targets. Little can be concluded with so few shots. Still interesting.

Chill Wills

The 2 Ruger Blackhawks I have has had 2 things done throats open to .452 and fire lapped the bores on both. I admit to not being the world's best pistol shot but I can say leading has ben drastically reduced using my cast bullets sized at .454.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |