can they be reformed from a parent cartridge?

|

|

|

can they be reformed from a parent cartridge?

I made some from old balloon head 45 Colt. They were thin enough I didn't have to ream them for bullet fit but you do have to thin the rim. Star Line sells 455 brass and it works just fine. Personally I wouldn't make any more 455 unless I absolutely had to.

BIG OR SMALL I LIKE THEM ALL, 577 TO 22 HORNET.

ELK HUNTER, thank you so muck for the reply. I think it will be cost prohibitive to use the 45 COLT.S. toot.

I made some MK1 length from 45 S&W brass. A lot of work for 20 cases, then I lucked out finding Dominion 455 Colt and I am a happy camper now.

Star-Line really missed the boat when they absolutely refused to listen to the many folks who asked them to make the .455 Mk I instead of the Mk II The longer case could have been trimmed to the shorter length but brass stretchers are out of stock, everywhere.

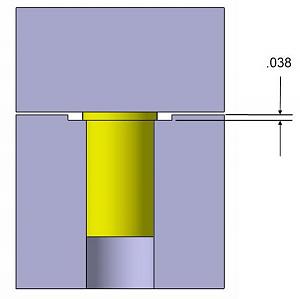

I make my .455 Colt brass from .45 long Colt brass; trim the rim thickness from the front in a mini lathe to about .037, trim cases to .45 ACP length and load with .45 Colt sizing die and .45 ACP seating die and Lee factory crimp die. I use .45 Auto Rim load data with .454 or .455 bullets. It is for a 1915 Smith & Wesson marked .455 Colt made for the Canadians.

Ogle, thanks for the reply. makes sense and is not completed. toot.

I make the Webley Auto brass from the Starline 45 Cowboy brass(#1640). It just about fits the revolver as is without any modifications, length is good and the rim is so close it fit a couple of un modified Webleys, (not mine of course) I guess if you have to buy brass and the right stuff isnt available then this cowboy brass is only a slight rim thinning away from the finished case. Im happy not having to trim... Naturally they are all out of stock.

SOFMatchstaff, thank you for the responce.

I do a process similar to Ogle, except I don't have a mini lathe. I file down the rim on 45 Colt brass to to .040 (originally of .060). You could chuck the case in a drill and make it faster. So the primer would now be standing proud of the case head if i seated it. To fix that, I have a primer pocket reamer and chuck it in a drill and uniform the primer pickets (basically digging it deeper as the rim in .020 thinner because I cut on the back of the rim). Then I trim it to length for my Webley revolver which is actually longer than even mk1 brass.

I use an MP mould of the correct hollow base, in 260 grains and .454" (if I recall correctly). I worked up a load with titegroup to get the velocity close to service load of 630fps.

Last edited by Archibald; 09-13-2021 at 01:32 AM.

Archibald, when you chuck up the case in a drill, or drill press? how you keep the case, case mouth from collapsing when you tightened it up to thin it down? when you say rim, do you mean where the web is or where the primer face part of the case is , on the bottom of the case?

Archibald, you're thinning the brass from the wrong side. find or make a safe edge file and take off the .020 from the front side, and dispense with the primer pocket BS.

Toot, try a 29/64 drill bit shank as a mandrel, only need about an inch or so to support the case internally, and jaws will grab and align the case well enough to use the safe edge file on the rim.

Still no cowboy brass at starline yet, It's still the fastest way to go,

years ago I bought a good supply of FIOCHI, loaded ammo. so I am all set. it pays to think ahead. when a bargain comes along. they are not cheep anymore.

will do. thank you for taking the time to answer my question. will do it, now that I know what I am doing.

Yep, Starline made a mistake not making Mk I brass. I asked them years back, even started GB inquire https://castboolits.gunloads.com/sho...ody-interested . No luck.

As for making Mk I brass, the easiest way is to use 45 Cowboy Special. Next is 45 Schofield. Don't waste time playing with 45 Colt brass, it requires reaming, too thick when shortened on Mk I length.

Regarding rim modification, don't bother with turning or filing, make a simple tool and just squeeze the rim using small hydraulic press or strong machine vise, every milling machine has one. Make tool from tool steel and rim thinning is the snap:

Last edited by Onty; 09-27-2021 at 07:01 AM.

The first .455 Webley brass I bought was .45 Colt cut down but had to use a .45 Colt shell holder with it.

Steve

"The Original Point and Click Interface was a Smith & Wesson."

Life member NRA, USPSA, ISRA

Life member AF&AM 294

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |