Hey Folks,

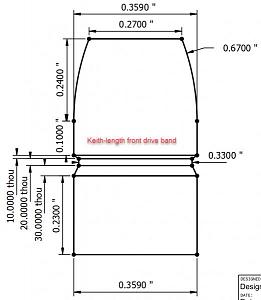

I recently picked up a S&W M60 in 357mag (3"), and I am now in search of the ideal boolit design for it. In my experimenting, it seems to be fine with the Lee 358-158 RF when powdercoated, but I'm interested in a NLG design and like the idea of a custom that keeps the large meplat. For giggles I used the Accurate 36-158V as a starting place, removed the lube groove, cut 0.050" off the bottom so slightly less is seated in the case (about the same as some 125gr SWC) and moved that length to the front drive band above the crimp groove - it is now a Keith-approved 0.100". According to my measurements, the maximum length a boolit can extend beyond the case mouth before interfering with cylinder movement is 0.375", so I believe the front-heavy design will fit OK.

I'm kind of operating in a vacuum in terms of design philosophy and accepted procedure, though. Is this line of thinking how folks usually go about it?

|

|

|

Reply With Quote

Reply With Quote