I have an new 314299 Lyman iron mold, how much break in should I expect? I've been casting with Lee Alum molds and never had an Iron mold. The only problems I've had was weight variations, once the molds are up to temp.

|

|

|

I have an new 314299 Lyman iron mold, how much break in should I expect? I've been casting with Lee Alum molds and never had an Iron mold. The only problems I've had was weight variations, once the molds are up to temp.

The stearic acid as flux began because I had some I wasn’t using. I have switched to plain wax. I will keep using sawdust, but only slide it over the top of the lead, not pushing it down while I stir. Pushing down resulted in a lot of debris down in the pot, and clogged my nozzle. The sawdust grabs objects the wax won’t.

*

I left a skin of wax on top of the molten lead while casting today. It lasted 45 minutes or so, before completely burning away. When I shut the pot down, I let some wax melt over the top surface of the lead as a overnight protectant. Last time I left my pot full, the lead pulled away from the walls of the pot and I think some rust stated in the gaps, so now the surface is coated. The coating will burn and flux at start-up tomorrow. Hopefully it works out as well as I hope.

*

If I ignore the first casting, my boolits today weighed 126.3 +/-0.5 grains.

Do these get sticky after a while?

I made one casting that turned out frosty (mold temp pre-warmed to 475F). I pan lubed and sized with the Lee sizing die. I found that half of each side of the parting line was not sized, as if the two sides of the mold are not properly aligned.

Is this an issue with the mold, or me?

*

These two pictures show the same boolit rotated 180 degrees. Material being swaged/removed on the right side of the parting line for both of these is what makes me think the two mold halves are misaligned.

How many did you cast ? Were they all like that ? Did you preheat the mold laying on a hot plate ?

I casted 30 pieces. I let the mold get a little extra hot on the last set, and only that set came out frosted. I’m preheating with a toaster oven, which is crazy slow. I’ll try a propane stove & pan as a free hot plate next time.

*

I think I can see eccentricity on the samples that are not frosted, but the eccentricity isn’t quite as visible without the frosting.

*

I understand how to get rid of the frosting, but the eccentricity is what I don’t know how to fix.

My questions were wondering if the mold was heated unevenly and if that could cause that . If uneven heat did that then it might go away after casting a bit and had a chance to heat evenly not that I know heating uneven would cause that . It may be a bad mold .

Looking forward to hearing other comments .

What mold are you using? If it is a Lee 2 cavity with the horizontal alignment pins, they can get out of alignment if not closed just right. Try setting the open mold on a flat surface and closing it while in contact with the surface if it is that type of lee mold.

God Bless, Whisler

Placing the boolit in the lube-sizer "off axis" (not vertical) can and will swage material from each side of the boolit's driving band - though opposite in position and not like that single boolit rotated 180*.

Is your nose punch correct? Flat nose punch - right? Is it well seated and locked down in the lube-sizer?

Your mold might not be circular/cylindrical. It may be warped, elliptical, and out of round (exaggerated dotted line being removed by lube-sizer [solid circle]).

[LATE NOTE: I see it is a new mold (358-124-TC-R4 5 Cavity PB from NOE). I don't know how all 5 cavities could be warped - maybe, but probably not. I cannot get my mind around the SAME BOOLIT pictured 180* rotated above and the DRAMATIC cut off "ramp" right at the mold line exactly across the mold diameter!

too weird]

Frosty boolits are indicative of the melt being too hot, the mold being too hot, or both! Cool it down a bit. Don't fuss over the pre-heat temperature. Dip the mold in the melt until "hot enough" that it "sloughs" the alloy. Dip the spru plate as well.

Last edited by Land Owner; 03-24-2021 at 08:19 AM.

If it was easy, anybody could do it.

I haven’t had a chance to cast again to try and fix the issue, but these sketches describe what I believe is the case. Here are measurements from three parts cast on the same day:

A = 0.3581”, 0.3586”, 0.3586”

B = 0.3604”, 0.3597”, 0.3598”

C = 0.3568”, 0.3575”, 0.0.3575”

Measurements taken with a Starrett micrometer. The positions of B & C are held by eye, so the 15 degree shift from the parting line is variable.

I’m concerned this >0.002” eccentricity will cause leading of my barrel.

It’s the mold. Back in the shop now, and the two mold halves have a bit of play when put together. I’ll call NOE tomorrow and see if this is within tolerance.

I'm wondering about cleaning. I once forgot to use brake clean followed by soap and water on a new mold and the residue of oil from manufacturing created all sorts of issues. Including bubble like pitting that reminded me of what one gets when using a muffin tin with non-stick coating that off gasses until it gets properly burned off by repeated filling and dumping ingots. Lot of little pits like tiny bubbles had popped.

If one is unsure of mold temperature being "right" one can always try dipping a corner of mold into molten lead, in a short time mold will probably be too hot, then cast a few with long wait times for sprue to cool. On the way down to a good casting temperature one will have eliminated too cold a mold because the thing started at too hot.

Foreign substances can tend to bubble as they boil under the hot lead was my first thought when I heard the defect described as "rough". As to the question of sticky with pictures of defects with cause and cure would probably be useful.

Scrap.... because all the really pithy and emphatic four letter words were taken and we had to describe this source of casting material somehow so we added an "S" to what non casters and wives call what we collect.

Kind of hard to claim to love America while one is hating half the Americans that disagree with you. One nation indivisible requires work.

Feedback page http://castboolits.gunloads.com/show...light=RogerDat

I have sometimes wondered if I use too much pressure on long multi cavity molds if I might cause some shifting of the mold block alignment due to pressure in the center creating a bit of a shift due to bowing or because the molds are being pressed hard all the way in one direction on the alignment pins. I have a 5 cavity 38/357 mold that will show a faint mold seam when I squeeze the handles too hard, not there if I relax a bit. I think the heavier mold causes me to use a heavy grip.

Scrap.... because all the really pithy and emphatic four letter words were taken and we had to describe this source of casting material somehow so we added an "S" to what non casters and wives call what we collect.

Kind of hard to claim to love America while one is hating half the Americans that disagree with you. One nation indivisible requires work.

Feedback page http://castboolits.gunloads.com/show...light=RogerDat

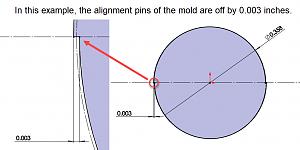

What I see is your mold halves are not in alignment. .003 off in your drawing. Bottom shifted to the right top shifted to the left. The parting line on the boolit shows one side of drive band sized more than the other. My guess if it is only one cavity doing this it is a milling error, OUT OF ROUND, all cavity's probably alignment pins. YMMV

NOT A PROFESHANL

"Any man who thinks he can be happy and prosperous by letting the government take care of him; better take a closer look at the American Indian" Henry Ford

I do not float my mold in the pot , put it on a hot plate or on top of pot while it is heating , but do not get mold over heated or you can warp it as to smoking the mold I have and Lee and NOE both advise it , it is up to you if you do or not it has not hurt any aluminum mold I have done it to .

Frosty is hot melt and a hot mold , back it off a bit , are you measuring temp. ? As to what temp. your thermometer is not always right PID on my pro melt 2 has me running a higher temp. then some are saying to use to keep spout from freezing and alloying flowing and I am not getting frosty bullets , used a pot for a long time with no temp. measurement , the alloy you are using will tell you what it likes and the bullets will show you , wrinkled , voids, rounded bases and bands rounded will tell you cold alloy contamination incomplete pour or not enough sprue puddle to cold of melt or to hot , mold to cold or to hot , Cast more at a session see if it starts to run better , when I am having a mold with issues , I find if I keep going and dropping bullets to check every few casts until they start looking like I want, if they do not look right I adjust temp of melt , temp of mold and keep casting after a hour see how they look set mold on hot plate sort bullets while pot is melting more alloy and coming up to temp .

If you have to many rejects , are the rejects consistent of the same defect or not and adjust casting technique from there . Practice does make one better at this .

I agree with huntnman , for some reason the mold does not appear to be closing in alignment .

Both mold faces should be clean of lead as well as the alignment pins and holes and the blocks should be loose float on the handles , so the mold can self align when the mold is closed. But if any of these issues are there I usually see flashing around the mold joint on the bullet when it drops , if the mold and lead are up to temp if they are not hot enough the lead may set up before it can flow between the mold halves to give you the flashing so the problem is less obvious .

Wish I had something more to offer.

I am a million bullets from qualifying as an expert on most anything cast bullet related, but what you described (red text) sounds like the alignment pin/s got bumped or were installed too deep. Not familiar with NOE molds, but I'd think they can be bumped out a bit. I'd also think you could drive yourself nuts (and possibly screw up the mold) chasing the pins in and out between too short and too long.

Waiting for more knowledgeable casters to shoot down or correct my observation. I sure wouldn't start pushing alignment pins around based only on my thoughts.

“Some people spend an entire lifetime wondering if they made a difference in the world. But, the Marines don't have that problem.” Ronald Reagan

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |