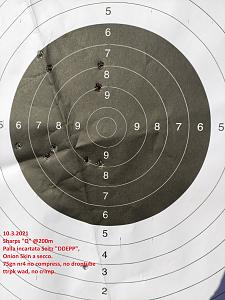

Hi all, this is my first attempt shooting PP bullets at 200 meters, 75gn swiss nr.4, no droptube, no compression, dry wrapping with Onion Skin paper. The bullet is a double diameter from a project by Arnie Seitz, it's a Lyman #2 alloy, the rifle is a Pedersoli Sharps "Q". The weather was windy with strong gust winds. The next time I'll try using a slightly thicker paper, just to chamber the cartridge with more pressure. Any suggestion is welcome.

|

|

|

Reply With Quote

Reply With Quote