Tyler, yes. haven't got to posting pictures yet, but it works well.

|

|

|

Tyler, yes. haven't got to posting pictures yet, but it works well.

GWS, you are also a great contributor. no, haven't got pictures posted yet. I'll figure it out. I do have some pictures posted to the lee sixpack face book page. under hiwayman. for whatever reason, cast boolits wouldn't recognize my sign in and I had to create a new account. but I'm still just the ol hiwayman.

I wish! Unfortunately, I would need to get a bigger printer, which doesn't sound like the worst idea!

Thanks again to everyone that made this project into what it is, it is truly impressive!

Has anyone used an M18 prox switch with 10mm sensing distance instead of the 14mm?

Has anyone printed Mike's primer tube filler device? I just found on TV and I'm working through the latest version, but its 2019 and wondering if they are old, or still useful...

https://www.thingiverse.com/thing:3412779

I'm going to break down and print another base. I have enough stuff to make another minus motor and relay, so why the heck not I suppose. May even try out ASA. Have a decent profile worked up for it and have had good luck. Let us know how it comes out, I'd be interested in making one as the vibraprime can be ornery, like me.

Sent from my Pixel 5 using Tapatalk

So far it seems to fit together well. I printed the lower on 1mm nozzle with left over spools and the upper (green) at 0.3mm nozzle. I'm waiting for motor and controller parts to come in tomorrow. But threw primers in and manually seem to right themselves well.

Only thing that might be an issue is the ribs used for flipping the primers might be too small and close together, if I redesign I'll spread them out like the Lee shakers do it. But I'll wait until I finish it to mod it...

Looks like you updated the downtubes 5 months ago? Printed my downtubes a year ago. So I will roll with it and see if the shorter ones work ok, if not will reprint the downtubes.

Thanks for your work on this! I created a 1" tube table mount if you want to add it to your file database. Works with #8 screws or t channel clamps.

Morning Folks. Another small QOL adder for the project, a mirror mount. This will fit both the standard and 300 versions, no clue on the mongo. It uses 2x M3x10mm screws to attach to the bowl and a cheapy Amazon clip on mirror that you pull the clip off of.

https://thangs.com/mythangs/file/1000062

Is there an offset that fits the bullet feeder die? I printed the size 11 from the AP files but it's a little big. I can use some tape to make it fit but thought I would ask.

offset adapters are designed to fit the lee APP inserts. you need the adapter between the two.

https://github.com/BF556/Feeder/blob...et_Adapter.stl

I have been following this for a long time, Have most of my parts ready to assemble this weekend, Cant seem to find what the best spring size would be for 125 grn coated 9mm bullets. I have a double AA large spring, that I had purchased Back when I was acquiring parts for the Ammo Mikes feeder a couple years back, Is there a better option?

I donít have any input on a better spring but the one you have is what I use for coated Bayou 9MM.

This is what I use for all 9mm from my set up sheet. I did polish the insides of the #9 spring adapters and drop tube with fine sandpaper though for use with 38 SPL also.

GD

Collator Plate, 9mm bullet, Printed-custom

Plate Speed, 70%

Flipper, not necessary

Slide Plate, #5-no screw adj., Printed

Spring Tube Adapters, #9, Printed

Spring tube, Output Spring small, DAA

Drop Tube, 9, Printed-custom

Prox Holder, Printed

Prox Sleeve, Printed

Bullet Feeder Die, 35 Cal-upper holes, Lee Precision

Last edited by Gillie Dog; 02-01-2024 at 11:35 PM.

#2 member of the 10%ers

Howdy all. I have been admiring this project for a while now. Thanks to everyone that has contributed.

Need some quick advice. I cant quite figure out what options to check in the parts generator. I have an Ender 3 V3. Love the auto bed leveling vs my old upgraded Ender 3 Pro. So I am limited to 220x220. Which is OK because my volume will be fairly low. Shooting IDPA a couple times a week.

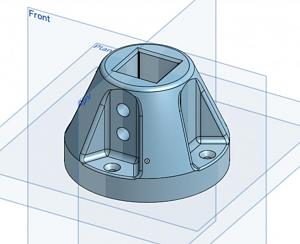

So I assume it will be this body: Main_Body_M634JS.stl

Question: Does the parts generator modify the Main_body based on selections?

Appreciate any feedback.

This is what I think I need at this point. Not sure about collator plates and their differences.

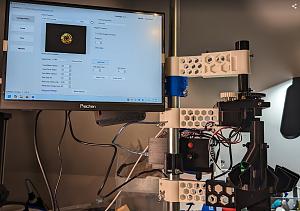

I need to feed this thing. Just finished it. Need to hide the wires and train it now that it up and running.

No it does not make any changes in the main body (or anything else) based on selections, it just puts it in the parts needed for the project. Project generator just makes parts list and assembles files for you to print.

That body is for the 634J motor of course.

Now you just need to get printing............... Have at it.

GD

#2 member of the 10%ers

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |