|

|

|

Last edited by calgarysparky; 08-11-2023 at 03:39 PM.

Bullet slide or case slide? Now I'm confused too.....

sparky, that's how much I know......didn't know you could print quality with a .6 nozzle at .25mm. That would speed things up over printing .4, at .2 high. for sure. Small parts I print .4 at .12mm layer height, longer, but I love the quality and fit.

Last edited by GWS; 08-11-2023 at 04:52 PM.

So yes, Mongo brass slide was intended to say.

And that said, I took the Mongo brass slide and moved the hole out 2mm for more clearance with small pistol brass collator plate and the back of the hole is still behind the large pistol brass collator plate. Then took the brass slide and moved its hole 4mm out to try to get lay-down 30 Carbine to work better closer to center of hole, helped but not perfect. Printing another stand-up collator plate for 30 Carbine right now. This case has been difficult for me. Lay-down I get it to be pretty good with custom collator plate I did but its head is so light it takes a good length to tip down the slide hole when head is in back, head first is OK but speed has to be watched or you get stove piping with the adjuster set at 24mm hole opening to make it work. About 1 every 200 is not happy and jams, can be either direction. Stand-up has been better and just need to "perfect" the collator plate, to my satisfaction, of course, which with my OCD means perfect collating and efficient.

The journey is an enjoyable endeavor though and the filament makers really like me.

Many thanks guys.

GD

Last edited by Gillie Dog; 08-12-2023 at 08:25 PM. Reason: Spelling--

#2 member of the 10%ers

You and me both my friend. Glad to hear it is working with some trial and error. As GWS has said, part of the fun is the journey to success. The number of failed plates I printed is impressive. At one point I estimated about 20 rolls of filament. All in the name of progress. haha

The only part I print at .12 with a .4 is the bullet feeding die for clearances. certain parts get .4 at .2, but the bowls and plates get .6 at .25. I have 6 printers set up with different nozzles and such so I put together a system in under 24 hours. This is my 6th unit now so I've had the chance to play around with stuff. If you're wonder why six, I had a hornady LNL AP that I built 2 for and a buddy wanted it so those went with that press. I have a 550 and a buddy wanted a bullet feeder for his 750 so he got one. The I switched to a Lee SPP and built 2 more for it, LOL. The 300 is for my APP and soon to come case collator. Plus I et bored easily so I just build stuff, ROFL.

Bro, six printers with different nozzles?

You sound like me. I print mostly just for something to do these days, not because I have a pressing need. Needless to say I have a few collators. Glad to hear you are setting your friends up. Exactly why I published this project.

Last edited by GWS; 08-13-2023 at 12:22 AM.

Awesome thread!

Some help and guidence would be utmost appreciated mates!

I am an epic level greenhorn-noob so I write in hopes of some advice on what boxes to check and parts to get?

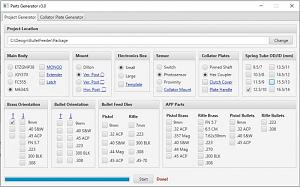

(I got myself one of them 3D printers with 250mm cubed sized build plate, a 1kg roll filament, superglue and I downloaded the github .zip and fired up the "parts generator.jar".)

First aim is to make a 9mm brass collator headstamp up.

1/ What motor is the strongest/best choice? There are 4 different motor choices in the .jar generator?!!? (Links would be appreciated, Swede so Amazon.se I presume?!?)

2/ What boxes would you advice I check in the "parts generator.jar" software for the above adventure?

3/ What is the biggest version I can do with cubed 250mm build plate?

What is the "Spring" choices, what is correct for 9mm brass?

Also what is "APP parts" selection?

Thanks for any help or advice, look forward for your expertize!

May the force be with you mates,

/Silverbullit

Last edited by Silverbullit; 08-15-2023 at 02:00 PM.

Awesome thread!

Some help and guidence would be utmost appreciated mates!

I am an epic level greenhorn-noob so I write in hopes of some advice on what boxes to check and parts to get?

(I got myself one of them 3D printers with 250mm cubed sized build plate, a 1kg roll filament, superglue and I downloaded the github .zip and fired up the "parts generator.jar".)

First aim is to make a 9mm brass collator headstamp up.

1/ What motor is the strongest/best choice? There are 4 different motor choices in the .jar generator?!!? (Links would be appreciated, Swede so Amazon.se I presume?!?)

2/ What boxes would you advice I check in the "parts generator.jar" software for the above adventure?

3/ What is the biggest version I can do with cubed 250mm build plate?

What is the "Spring" choices, what is correct for 9mm brass?

Also what is "APP parts" selection?

Thanks for any help or advice, look forward for your expertize!

May the force be with you mates,

/Silverbullit

Have you read the user manual in the downloaded files? It will address a lot of the "noob" questions.

https://github.com/BF556/Feeder/blob...r%20Manual.pdf

Hi TyleR,

U the MAN!!!

In short Yes, however my english is not quite all that as it comes to technical terminology.

The User Manual is actually awesome beyond belief, probably the most thorough on the point, no unneccessery stuffing User Manual I've seen to date.

The conundrum is my lack of english skills and the humbling reality that the online translators or translation lexikons is an absolute unusable disaster when you try to translate through those misleadingly abundant sources but in reality pseudo guessing drivel at the technical perifieries.

Thus a lot of boxes are muddy in my usually tar-pit rubbery rails carrying my train of thought.

Stuff like the box with Hex Coupler, is that for the 634 motor?

And options, should I go for latch mode or skip that one? (is it compatible with not using latch if its not necessary)

The APP parts... not quite able to guesstimate what this is

Some parts from the great purchase links are not availible, some googling steer me towards building it with the microswitch option first.

Should I get the Relay and the speed controller for this initial build based on the Microswitch option?

As soon as I have this sorted out I will place the order and start printing out stuff,

oh and try to wrestle the "Collator Plate Generator" Tab

Last edited by Silverbullit; 08-15-2023 at 05:47 PM.

[QUOTE=Silverbullit;5612748]

First aim is to make a 9mm brass collator headstamp up.

1/ What motor is the strongest/best choice? There are 4 different motor choices in the .jar generator?!!? 634JS. link is in the manual

https://www.amazon.com/Greartisan-Se...p?ie=UTF8&th=1

2/ What boxes would you advice I check in the "parts generator.jar" software for the above adventure? See attachment

3/ What is the biggest version I can do with cubed 250mm build plate? Standard size

What is the "Spring" choices, what is correct for 9mm brass? Feed springs. 10mm (ID) spring would work.

Also what is "APP parts" selection? For a Lee APP press

Stuff like the box with Hex Coupler, is that for the 634 motor? It is used to interface the motor with the collator plate. Hex or pinned motor shaft.

And options, should I go for latch mode or skip that one? (is it compatible with not using latch if its not necessary) I don't know what you are asking

Some parts from the great purchase links are not availible, some googling steer me towards building it with the microswitch option first. I looked at all the links in the latest version on github and they all seemed to work.

Should I get the Relay and the speed controller for this build? Yes.

As soon as I have this sorted out I will place the order and start printing out stuff,

oh and try to wrestle the "Collator Plate Generator" TabAll of the collator plates you should need are in the collator plates folder in the download.

Thanks TyleR,

That is some Golden answers!!!

I will place the order immediately, I'm adding the "SpeedController" & "Relay" to the order list while replying.

I will add updates and build pictures as we put our TyleR builds together!

One last question, is there an alternative Relay that works with this build?

(Asking since maybe I can get one here if theres an alternative and start building sooner, got itchy build fingers. hehe)

For some enigmatic reason the connection to Castboolits is horrible today, first time it did not work supernice. (Crashes out when I try to add pics)

It is much appreciated mate!!!

Cannot find something looking identical at the swedish amazon site, could these be same despite having cube shape?

https://www.amazon.se/GUUZI-Effektre...9BMQVMKH&psc=1

Printing out the brass headstamp up latched microswitch version right now! hehe (Oh boy it feels good!!!)

When that is done I will check the .jar boxes and print out bullet nose down/up latched microswitch version.

Cant stop once you get going with this!!!

Thanks again mate, will update on the adventures

Well yes, I wanted that but the proximity sensor linked/recommended seems nowhere to be found.

I really wanted that proximity sensor version but I ordered the microthingies since my googling the Amazon.se served me a migraine (due to low comprehension/knowledge *blush*)

Is there another proximity thing that would work?

And thanks some more, really appreciate your awesome feedback, it is helping me out A LOT!

Golden mate!!!

/Swedish fumbler.. .I mean Silverbullit

Supernice mate,

I found it immediately! (I think)

I will order 2 @ once before my boss comes home (g/f)

Purchasing like a shoppaholic right now!!!)

Last edited by Silverbullit; 08-16-2023 at 11:39 AM.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |